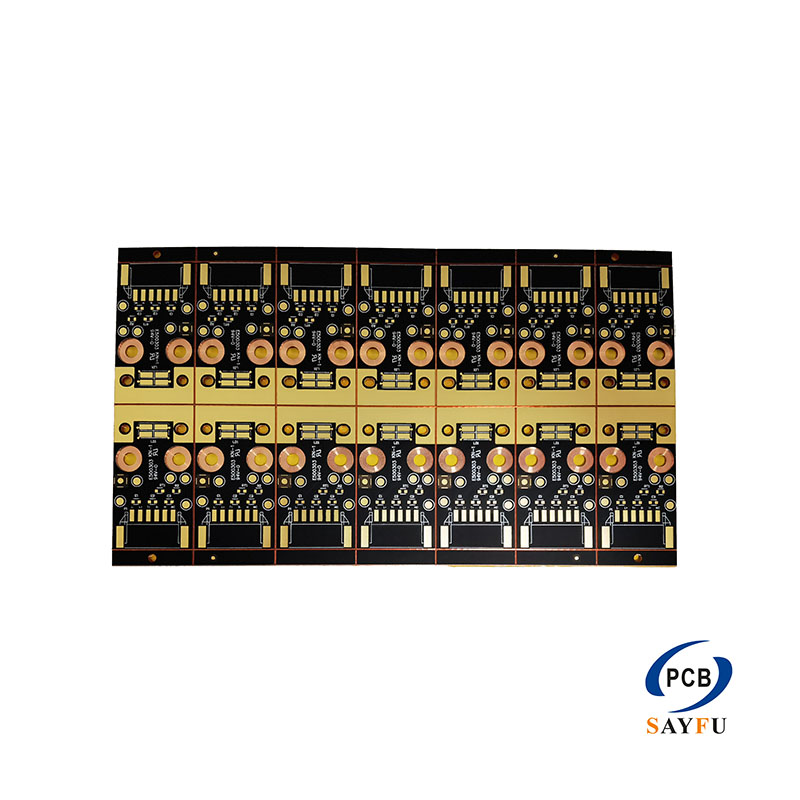

To measure the technological level of a circuit board manufacturer, the first thing that comes to mind is the number of layers of the production and processing circuit board. So the multi-layer circuit board is more strict in the process of production. The multi-layer circuit board needs to sink copper in the hole, so that the hole has copper and becomes the electric hole. However, after inspection in the production process, it is occasionally found that there is no copper or copper unsaturated in the hole after copper precipitation. What is the reason for the absence of copper in the hole? What can do to improve it?

- Dust plug holes or thick holes.

- There are bubbles in the liquid when the copper is sunk, and the copper is not sunk in the hole.

- There is line ink in the hole, no protective layer, after etching the hole without copper.

- The acid and alkali solution in the hole is not cleaned after copper sink or plate electricity, and the parking time is too long, resulting in slow bite.

- Improper operation, staying too long in the process of micro-etching.

- The pressure of the punching plate is too large, (the designed punching hole is too close to the conductive hole) and the middle is neatly disconnected.

- Poor penetration of electroplating liquid (tin, nickel). To improve the causes of copper – free holes.

- Add high-pressure water washing and rubber residue removal procedures for holes that are easy to produce dust (such as holes with a diameter of 0.3mm or less).

- Improve the activity and shock effect of the potion.

- Change printing screen and counterpoint film.

- Extend the washing time and specify how many hours to complete the graphic transfer. Set a timer.

- Add explosion-proof holes. Reduce the load on the board.

- Do regular penetration tests. Then know that there are so many reasons will lead to no copper open hole, but also every slice analysis? Should we go ahead and prevent supervision.

Does it help you to know the reason why there is no copper in the hole of the circuit board and how to improve it? Sayfu has more than 15 years of production experience in the PCB industry, welcome all customers across the country who need circuit board to inquire, but also welcome to visit our company.