Printed Circuit Board Assembly Service ( PCB Files & BOM List, please send to [email protected] ( Fast Quote ) . For more information kindly check our website: www.winowpcba.com

What is a Prototype PCB Assembly?

There are many names for prototype printed circuit board (PCB) assemblies. Other names you will commonly hear are: surface-mount technology (SMT) PCB prototypes, PCBA prototype assembly, PCB sample assembly, etc.

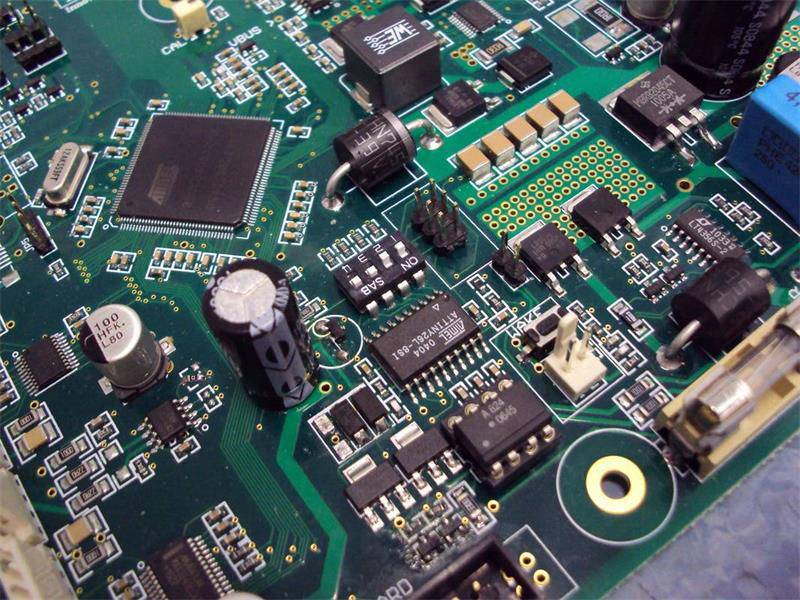

The term prototype PCB Assembly refers to a fast prototype PCBA used to test the function of new electronic designs. These help with quality assurance, verifying that there is no problem with the test product, finding bugs, and updating the design. Typically, before mass production, one electronic project will need 2-3 iterations of a prototype PCB assembly to make sure everything is working perfecty.

Winow supports engineers to assemble their electronic prototype quickly and cost effectively during the whole design verification process. To ensure that the product design meets requirements, in general, we suggest 5 pcb or 10pcs for prototype assembly testing. Of course, one or two piece is also OK, so long as it can be verified.

PCB prototyping has always been one of our most requested services, whether it’s PCB prototype fabrication or assembly. Our expert engineers will check and test your layout to ensure the correct prototype is fabricated and assembled on the first assembly run. Through our network of PCB component suppliers and SMT assembly engineers, we can ensure you a quick turn around and top quality circuit board. We offer low volume circuit assembly for prototyping with DFM and DFT to eliminate possible issues in your product.

Why choose Winow’s Prototype PCB assembly services?

Our company with professional PCB design concept, excellent PCB LAYOUT team, strictdesign process to provide customers with efficient and quality services.

- 90% of the technical staff have more than 10 years of industry experience, set up a PCB design department, to create more professional services.

- To provide PCB package construction for the customer (the customer provides the component DATASHEET).

- To provide PCB impedance calculation, lamination design, QA inspection, process inspection, EMC inspection for customers.

- The design includes high speed, high frequency, high power, simulation, digital and analog mixing, HDI, soft and hard combination, FPC and other design types.

- Master the most advanced technical information, fully consider EMI, EMC and manufacturability design, assist customers and LAYOUT engineers to do schematic diagram analysis and PCB design, to ensure the quality and reliability of the design.

- Support schematic diagram and PCB software formats: Cadence, Mentor ee, Mentor pads, Altium (99SE), etc.

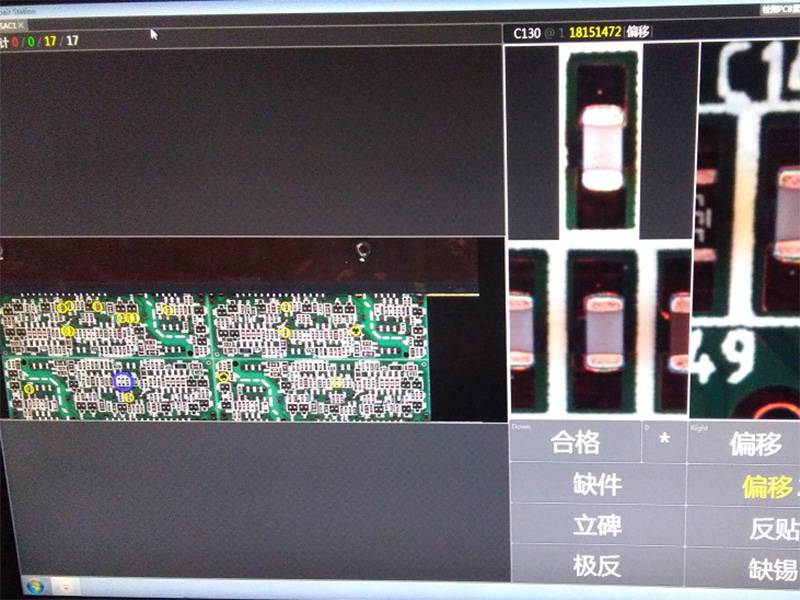

How to guarantee high quality PCBA assembly ?

- A team of specialists for engineering and technical services

- Technical data and specification analysis

- Customer Specification Analysis

- Technical files opening and check versus design rules

- TQ (technical question), if needed, will be sent to customer after files analysis

- Quality inspectors on site and in suppliers’ factories

- A fully equipped in-house laboratory to perform all PCB tests needed

- Annual audit & Spot audit

- Quality engineers for complete qualification and process

- All our partners are ISO9001, ISO14000 and UL.

- Most of them are TS16949

- And some are ISO13485, AS9100 and ITAR certified.

- Micro-Section:

Digital Microscope (Keyence VHX5000), Sample & Grinder Machine - Surface plating layer thickness measurement:

X-Ray System (Fisher XDML PCB 200)

Ionic contamination tester (Metronelec CT100-L)

Ageing test, HR content Oven (GWS EK-04)

Solderability test & Thermal stress test by Solder Pots - Mechanical Measurements:

Bow & Twist, Roughness, Mechanical, V-Cut, holes diameters,

2D Measurement (Keyence 6225)