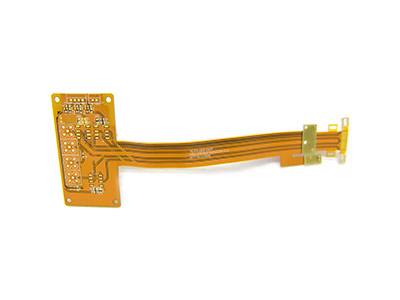

FPC board refers to single, double and multi-layer flexible copper foil substrates with polyimide (PI) or polyester (PET) as the base material, including adhesive and non-adhesive flexible copper foil substrates. The purpose of FPC board testing is to establish a general rule for the appearance and quality of FPC boards. The basis for judging the appearance and quality of FPC soft board products will help to improve the manufacturing technology and reduce the waste of resources caused by unnecessary scrap And environmental pollution. Test method The test method uses visual inspection, magnifying glass, and ruler as the main inspection methods and tools. If necessary, other applicable test instruments or equipment may be used for inspection.

Basic testing standards:

- The appearance of the substrate film surface;

- The appearance of the covering layer;

- Deviation of connecting plate and covering layer;

- The seepage of adhesive and cover coating;

- The conductor under the covering layer changes color. After a 96-hour humidity resistance test at a temperature of 40°C and a humidity of 90%, it must still meet the requirements of voltage resistance, bending resistance, bending resistance, and welding resistance;

- Missing coating of the coating layer;

- Poor electroplating combination.

Precautions:

The conductor part of FPC needs to be treated with surface plating (anti-rust), such as plating, gold plating, OSP, tin plating, etc. The storage environment should avoid corrosive gases, and the temperature should be controlled at 20 /-5 degrees Celsius, and the relative humidity should be controlled within the range of 70% R.H. Under the above storage conditions, the effective shelf life of the product is 6 months after leaving the factory.