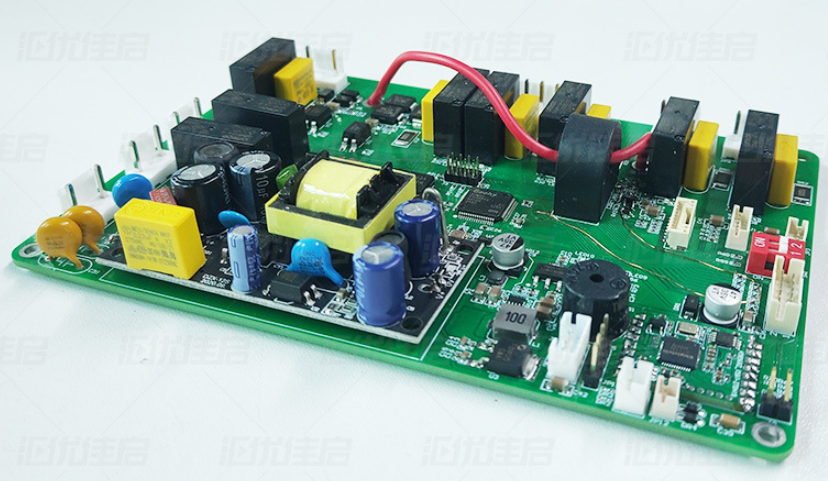

PCB Assembly in Shenzhen China brings circuit designs to life. It builds functional modules on bare boards. This process is core to electronics manufacturing.

1.Core Process: Placement to Soldering

Surface mount technology has three key steps. First, solder paste printing applies paste precisely. Next, component placement follows. Machines position tiny parts accurately. Finally, reflow soldering creates permanent connections. Controlled heating melts the solder properly.

Moving to technical variations –

Through-hole insertion aids traditional components. It handles connectors and large parts.

2. Technology Extension and Quality Control

Strict quality control ensures reliability. Automated inspection checks solder paste. Post-soldering tests verify functions. Every step prevents potential defects. Consistency is guaranteed this way.

Considering its broader impact –

This process supports modern digital life.

3.Essential Modern Manufacturing

PCB assembly connects design and product. It combines multiple advanced technologies. This specialized manufacturing field is crucial. It supports everything from smartphones to industrial gear. Indeed, it’s a foundational modern technology.

4. Future Trends and Innovations PCB Assembly in Shenzhen China

The industry continues to evolve rapidly. Miniaturization presents new challenges. Components are becoming incredibly small. Furthermore, automation is increasing significantly. Smart factories utilize advanced robotics. This enhances precision and efficiency.

Additionally, new materials are being developed. They support higher performance demands. Environmental considerations are also crucial. Lead-free processes are now standard. Finally, IoT integration enables real-time monitoring. Data analytics optimizes production flow. Therefore, assembly becomes smarter and more adaptive. These innovations will shape tomorrow’s electronics. They meet evolving market needs effectively.

5.Global Market and Collaboration

The global supply chain is essential. It connects manufacturers worldwide. However, recent challenges prompted changes. Many companies now diversify suppliers. This reduces regional risks. Additionally, cross-border collaboration increases. Knowledge sharing accelerates progress. Specialized firms focus on specific areas. Such partnerships drive innovation forward. Together, we build better solutions for all. This interconnected approach ensures sustainable growth.This interconnected approach ensures sustainable growth worldwide.