In PCBA processing, two common soldering methods are reflow soldering and wave soldering. So in PCBA processing, what is the role of reflow soldering, what is the role of wave soldering, and what is the difference between them?

PCBA refers to the abbreviation of Printed Circuit Board + Assembly, that is to say, the bare PCB board goes through SMT loading, and then goes through the entire manufacturing process of DIP plug-in, referred to as PCBA. This is a common way of writing in China, and the standard way of writing in Europe and America is PCB’A, with “‘” added, this is called the official idiom.

It means that the solder paste pre-coated on the pad is melted by heating to realize the electrical interconnection between the pins or solder ends of the electronic components pre-mounted on the pad and the pad on the pcb, so as to achieve the electrical interconnection of the electronic components The purpose of soldering on the PCB board. Reflow soldering is generally divided into preheating zone, heating zone and cooling zone.Reflow soldering process: printing solder paste>mounting components>reflow soldering>cleaning

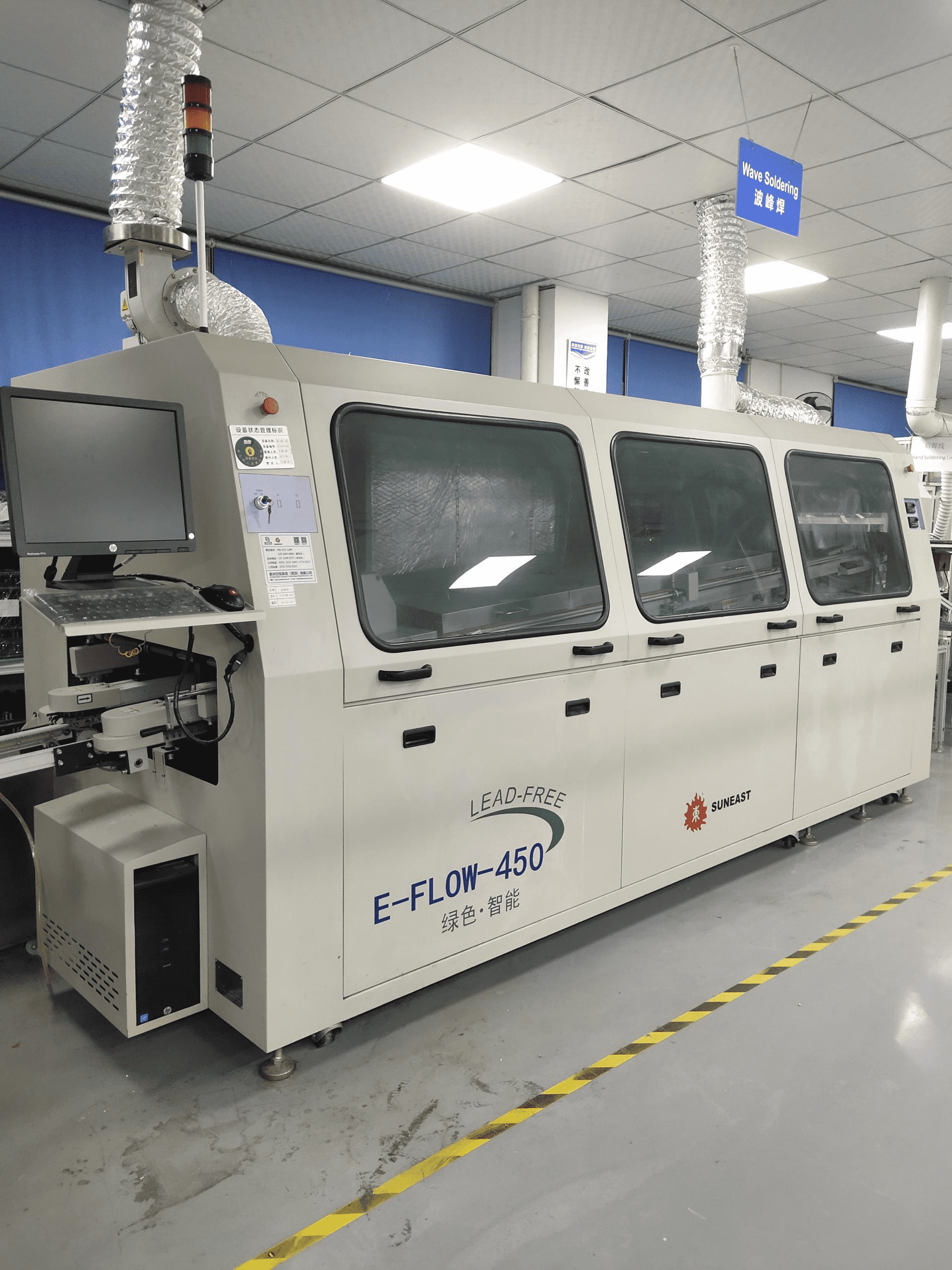

Use a pump to spray the molten solder into a solder wave, and then pass the pins of the electronic components that need to be soldered through the solder wave to realize the electrical interconnection between the electronic components and the pcb board. A wave soldering machine is divided into four parts: spraying, preheating, tin furnace, and cooling.

Wave soldering process: plug-in>application flux>preheating>wave soldering>cut corners>inspect.

(1) Wave soldering is where molten solder forms a peak of solder to solder the components; reflow soldering is where high-temperature hot air forms reflow and melted solder to solder the components.

(2) During reflow soldering, there is already solder before the pcb is applied to the furnace. After soldering, the applied solder paste is only melted for soldering. During wave soldering, there is no solder before the pcb is applied to the furnace. Complete the soldering on the pads to be soldered.

(3) Reflow soldering is suitable for chip electronic components, and wave soldering is suitable for pin electronic components.