With the further development of 5G, electronic products such as smart phones, tablet computers, and wearable devices are becoming more intelligent, miniaturized, high-frequency, high-speed, and highly integrated, and the components that need to be mounted on PCBs are also greatly increasing. At the same time, 5G smart products’ high-frequency, high-speed transmission and functions are greatly improved, and the requirements for screens are increasing, and the resolution is getting higher and higher. Power consumption has become a key point, and there is currently no new technology in the battery part. Breakthroughs can only continuously compress the space of mobile phone motherboards, and promote the continuous reduction of the size, total volume and volume of mobile phone motherboards.

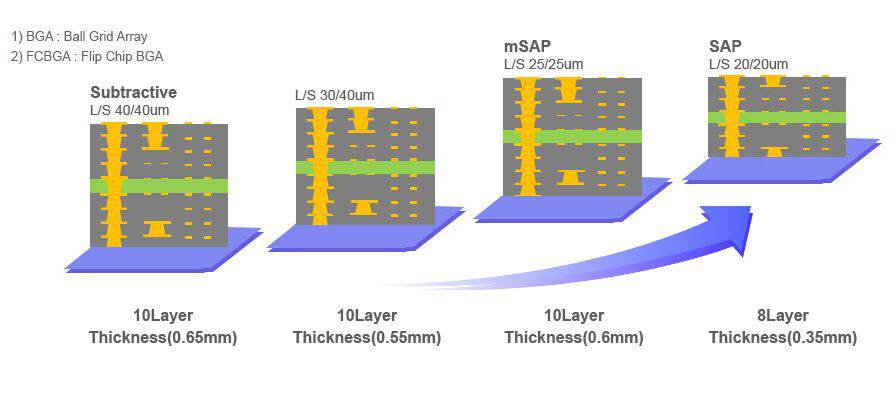

In the case of high integration and the inability to increase PCB space, PCB wiring is more dense, wire width and spacing are reduced, aperture and center distance is reduced, and the thickness of the insulating layer is reduced. However, the traditional HDI process capability is limited and difficult to meet. Therefore, the Anylayer arbitrary layer interconnection structure + SLP type carrier board technology (mSAP), which has more stacked layers, smaller line spacing, and can carry more functional modules, has become the best solution.

GUANGDONG SAYFU has achieved “breakthroughs in the production of high-end HDI circuit boards, such as any layer interconnection, minimum line width/line spacing, electroplating and filling of blind holes, interlayer alignment deviation control and other key technical difficulties.” High-current circuit boards, multilayer flexible printed circuit boards, rigid-flex HDI circuit boards, high-frequency and high-speed printed circuit boards have achieved good results, and the demand for HDI board orders has increased significantly.