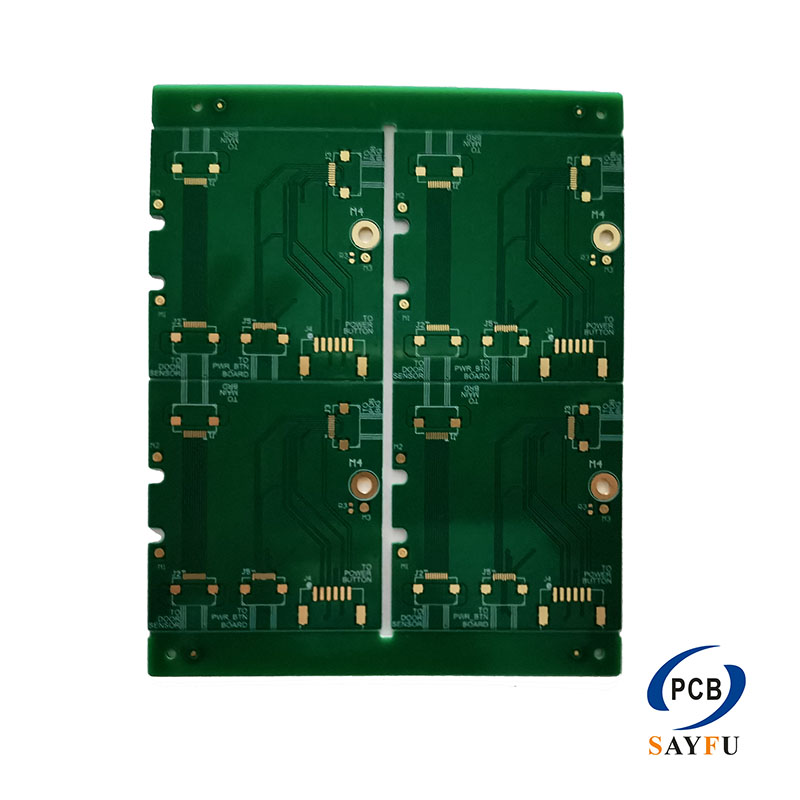

PCB enterprises in China, the Printed Circuit Board (PCB) manufacturing process is complex, demanding extreme precision, cleanliness, and efficiency. In this high-stakes environment, Automated Guided Vehicles (AGVs) have transitioned from a luxury to a strategic necessity. These smart, self-navigating carts are revolutionizing PCB factories by addressing core operational challenges.

1.Enhancing Product Quality and Yield for PCB enterprises in China

PCBs are highly sensitive to contaminants like dust, static, and physical shocks. Human handling, even with precautions, introduces risks. AGVs provide a controlled, automated material flow, minimizing human contact. This reduces the chances of electrostatic discharge (ESD) damage, physical scratches, and contamination, directly leading to higher yields and fewer costly defects.

2.Driving Operational Efficiency and Flexibility for PCB enterprises in China

PCB production involves numerous steps spread across large facilities. AGVs automate the linking of these islands of automation. They work 24/7, transporting panels between stations without delay. This creates a seamless flow, slashing idle time for expensive machinery and accelerating throughput. Furthermore, unlike rigid conveyor systems, AGV pathways are software-defined. This allows for easy reconfiguration for different product flows, offering crucial adaptability for high-mix, low-volume production.

3.Ensuring Traceability and a Safer Workplace

AGVs integrate with the factory’s Manufacturing Execution System (MES), providing real-time location data for every panel. This creates a digital thread, offering complete visibility into Work-In-Progress (WIP) for better planning. Finally, AGVs create a safer environment by eliminating manual lifting of heavy carts, reducing physical strain on employees, and navigating safely with advanced sensors.

In conclusion, for PCB enterprises, AGVs are not just about replacing manual transport. They are a holistic solution for improving quality, boosting efficiency, ensuring flexibility, and enhancing safety. By integrating AGVs, PCB manufacturers build a more resilient, competitive, and intelligent operation.

Looking ahead, the integration of AGVs with AI and IoT technologies will unlock even greater potential. This evolution towards smart factories will enable predictive analytics for maintenance and dynamic production optimization, further strengthening the competitive edge of PCB manufacturers in an increasingly demanding market.