一. Welding process

The so-called welding, is to use solder as a medium, that is, heating and making the two metals connected and achieve the purpose of conducting electricity.

1.Good welding basic conditions:

(1)Welding parts must have good weldability.

(2)The surface of the welding parts must be kept clean.

(3)Suitable flux is necessary.

(4)Welding parts should be heated to an appropriate temperature.

(5)Correct hand welding techniques.

2. Basic requirements for welding:

(1)The mechanical strength of the solder joints must meet the needs.

(2)Reliable welding to ensure good electrical conductivity.

(3)The surface of the solder joints should be smooth and clean.

二. Welding method and steps

1. Preparation before welding:

There will be an oxide film on the surface of the component leads, which affects the welding. The oxide layer must be removed first and then tinned. Except for a few leads with silver and gold plating, most of the components must be tinned before soldering.

- Five-step method of welding operation:

Preparation, heating, wire feeding, wire removal, and soldering iron removal.

三.Precautions for welding operation

- Keep the tip of the soldering iron clean.

When soldering, the soldering iron tip is in a high temperature state for a long time, and it is exposed to weak acid substances such as flux, and its surface is easily oxidized, stained with black impurities. Pay attention to rubbing away impurities on the soldering iron stand at any time. Wiping it with a damp cloth or sponge at any time is also one of the common methods.

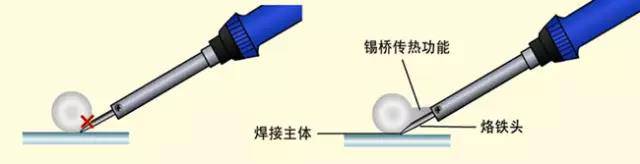

- Use the correct heating method.

- Heating depends on solder bridge.

- Use the correct way to evacuate the soldering iron, and the soldering iron should be removed in time.

- Tin dosage for solder should be moderate.

- The amount of flux should be moderate.

- Do not use the soldering iron tip as a tool for carrying solder.

- Solder joint quality requirements

The concept of the sayfu group is to understand the real-time needs of customers, to accurately analyze the market, to seek and develop feasible and complete project development plans. In 2017, winow New Energy Co., Ltd. (www.winowpcba.com) was founded, which not only expresses our determination to meet more needs of customers, but also shows the role of sayfu inthe future development of the PCB market.

The pursuit of efficiency and high quality is a never-ending step,we are committed to delivering high quality products to our customers in a tight timeframe and flexible to meet individual demands.