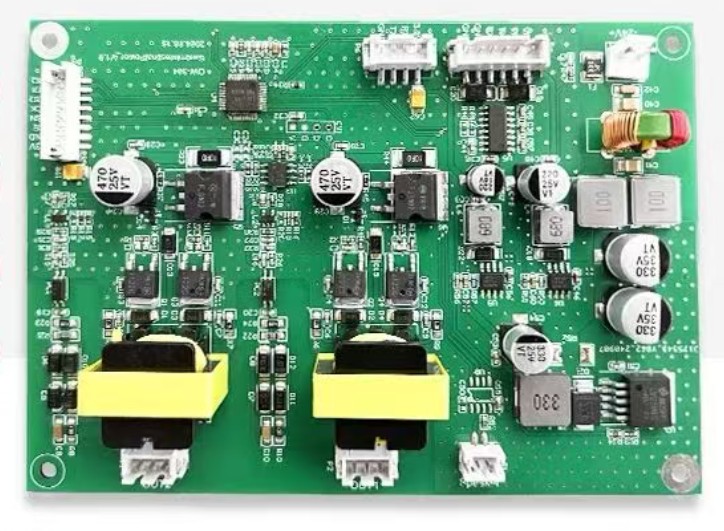

what’s Printed Circuit Board manufacturing, Printed Circuit Board (PCB) manufacturing relies on various specialized chemicals. These substances enable the transformation of basic materials into functional boards. Understanding their roles is crucial for quality electronics production.

1.Cleaning and Preparation Chemicals Printed Circuit Board manufacturing

The process begins with thorough cleaning. Alkaline cleaners remove organic contaminants from copper surfaces. Micro-etchants then create a rough copper surface. This roughness enhances adhesion in subsequent steps. Acidic cleaners eliminate oxidation and other impurities. Finally, rinsing with deionized water ensures perfect cleanliness. Proper preparation guarantees optimal chemical processing later.

2.Imaging and Pattern Transfer Chemicals

Photoresists form the circuit pattern on copper. Liquid photo-imageable resists are commonly applied. Alternatively, dry film resists offer different advantages. Developers then remove unexposed resist areas. This reveals the desired circuit pattern. Etch resists protect copper circuitry during processing. Strippers eventually remove resist after etching. Each chemical has precise timing and concentration requirements.

3. Plating and Surface Finish Chemicals PCB manufacturing

Electroless copper deposition creates conductive surfaces. This process enables through-hole connections. Electrolytic copper solutions then build up conductor thickness. Tin plating often serves as an etch resist. Solder mask inks provide environmental protection. Finally, surface finishes like ENIG are applied. Gold protects copper from oxidation while ensuring solderability.

PCB chemicals form an integrated system. Each substance contributes to the final product’s reliability. Proper handling and disposal are equally important. Environmental considerations continue to drive chemical innovations. Understanding these chemicals helps optimize manufacturing processes. This knowledge ultimately leads to better electronic products.

Modern PCB chemicals are increasingly eco-friendly. However, proper handling remains crucial. Always use personal protective equipment. Ensure adequate ventilation in work areas. Follow local disposal regulations strictly. Many manufacturers now recycle process chemicals. These practices protect both workers and the environment.

Waste treatment systems are equally important. They neutralize acidic and alkaline solutions. Filtration systems remove heavy metal contaminants. Water recycling reduces environmental impact. Regular safety training is mandatory. Proper chemical storage prevents accidents. Emergency showers must be accessible. These measures ensure sustainable manufacturing.