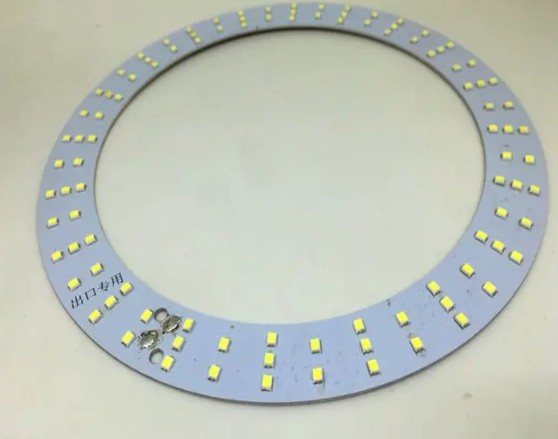

LED printed circuit board (LED PCB) is a type of circuit board specifically designed to integrate light-emitting diodes (LEDs). It is widely used in lighting, displays, and electronic devices. The production process is strictly controlled for quality to ensure high performance and high reliability. Every step from design to final testing is crucial to meet various application requirements.

The production process of LED printed circuit board

The production of LED PCB begins in the design stage. Engineers use CAD software to create the circuit layout, ensuring that the placement and connection of LEDs comply with electrical requirements. Next, the substrate material is selected, typically FR-4 glass fiber board, as it has good insulation and heat resistance. Then, the circuit pattern is transferred to the substrate. The etching step is then carried out, where the excess copper layer is removed using a chemical solution, leaving the designed circuit. The drilling process creates installation holes and through holes on the board to facilitate subsequent component connections. Afterwards, electroplating is performed to increase the conductivity and corrosion resistance of the copper layer. Finally, LEDs and other components are soldered in place using SMT or DIP. The entire process emphasizes automation and environmental protection to minimize errors and waste.

Quality Assurance and Testing

After the production of LED printed circuit boards is completed, strict quality control is of utmost importance. Firstly, electrical tests are conducted to check if short circuits, open circuits, and impedance meet the standards, ensuring reliable circuit connections. Optical tests evaluate the brightness, color temperature, and uniformity of the LEDs, using professional instruments to measure the light output parameters. Environmental tests simulate actual usage conditions, such as temperature cycling and humidity exposure, to verify the durability of the boards. Additionally, visual inspection systems automatically scan for solder joint defects or misaligned components. Through these tests, manufacturers can ensure that LED printed circuit board operate stably in various applications, extend product lifespan, and enhance user satisfaction. The entire process combines advanced technologies and strict standards, reflecting the innovation and reliability of modern electronic manufacturing.