The key differences between Wangling WL-CT350 PCB board and Rogers RO4350B

Wangling WL-CT350 PCB material is produced by a Chinese factory and is designed to compete with and replace the Rogers RO4350B high-frequency circuit material. Although both have highly similar key electrical parameters (such as dielectric constant Dk ≈ 3.5 and loss factor Df ≈ 0.003), and both use a ceramic-filled hydrocarbon polymer system and are compatible with FR-4 processing technology, there are undeniable core differences between them. These differences mainly stem from brand reputation, technical depth, subtle differences in raw materials and manufacturing processes, ultimately influencing their selection and performance in specific applications.

The core advantages and positioning of the Wangling WL-CT350 PCB

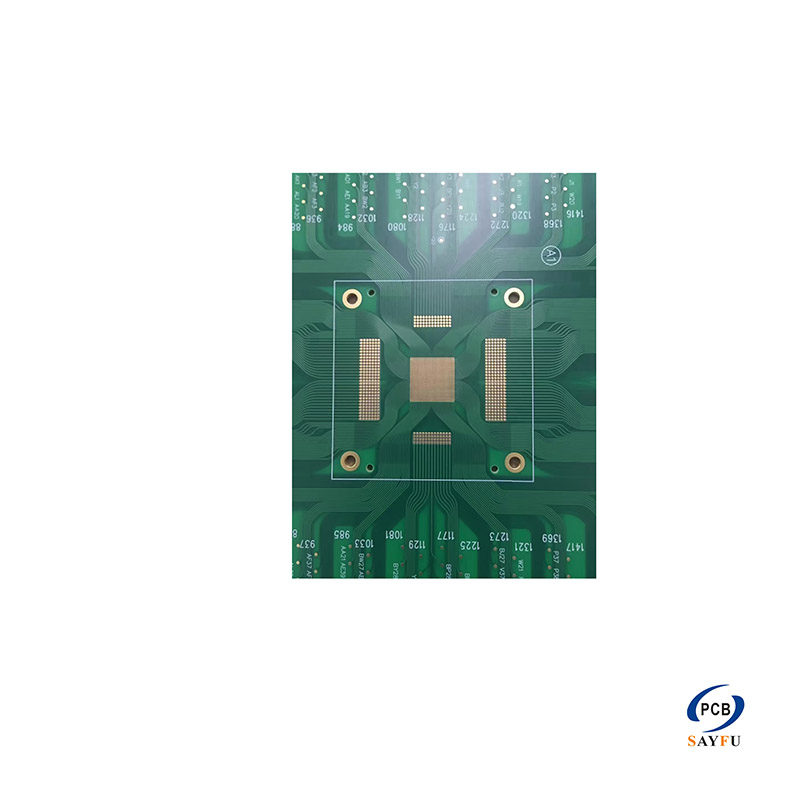

The main advantages of the Wangling WL-CT350 PCB material lie in its outstanding cost-effectiveness and localized services. The WL-CT350, as an outstanding domestic product, usually offers more competitive pricing compared to Rogers RO4350B. It can significantly reduce material costs for budget-sensitive or large-scale production projects, such as 5G base station antennas, automotive radars, and satellite communication terminals. Moreover, relying on the domestic supply chain, WL-CT350 is often more flexible and efficient in terms of delivery cycle, technical support response speed, and sample acquisition convenience. For projects that aim for independent control of the supply chain, WL-CT350 provides a reliable and cost-effective domestic solution.

Reliability considerations

Rogers, as a global leader in high-frequency materials industry, its RO4350B has a market validation history of over 20 years and has established an extremely high brand reputation. Its core advantage lies in the globally recognized reliability data, which is crucial for projects that pursue ultimate performance, long-term stability, and require certification from top global operators (such as core network infrastructure). Although Wangling WL-CT350 has rapidly caught up in performance, it has relatively less reliability data accumulation in broader application scenarios and over a longer period. The consistency of different batches of products is a factor that high-end users will pay close attention to when making a choice.

Summary

Choosing between Wangling WL-CT350 PCB and Rogers RO4350B involves a trade-off between performance, cost, supply chain, and risks. If the project budget is tight, there are requirements for domestic production rate, and the application scenario is for mainstream domestic communication equipment, then WL-CT350 is an extremely attractive option. On the other hand, if the project is targeting the top international market, is extremely sensitive to failure costs, and requires the most complete historical data support, then Rogers RO4350B is still a more conservative and reliable choice. Before making the final decision, it is strongly recommended to conduct small-scale trial production and comprehensive performance and reliability verification.