Precision vehicle PCB form the electronic backbone of modern vehicles, enabling critical functions from safety to autonomous driving.

The Precision Circuits Driving the Future of vehicle PCB

In modern automobiles, PCB serve as the “nerve center” of electronic systems, from engine control to advanced driver-assistance systems (ADAS). Their reliability is directly critical to vehicle safety and performance.

Stringent Requirements in Harsh Environments for vehicle PCB

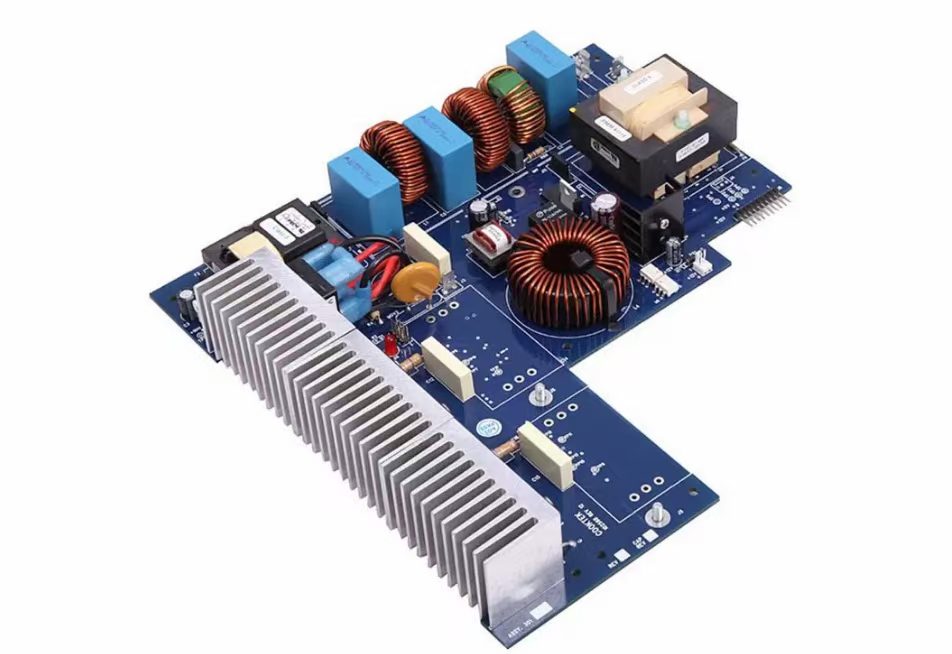

Automotive PCBs must withstand extreme temperatures, vibration, humidity, and electromagnetic interference. For instance, PCB in the engine compartment may operate in environments ranging from -40°C to 150°C, which standard consumer-grade PCB cannot handle. Therefore, materials such as high-temperature-resistant FR-4 or metal-core substrates (e.g., aluminum) are commonly used, with additional protection provided by potting compounds and conformal coating processes.

Key Application Scenarios

- Powertrain Systems: Engine Control Units (ECU) rely on multi-layer PCB to precisely manage fuel injection and emissions.

- Safety Systems: PCB for airbags and Anti-lock Braking Systems (ABS) must meet zero-defect standards.

- Smart Connectivity: Autonomous driving sensors (radar, cameras) depend on high-frequency PCB for low-loss signal transmission.

Technological Trends for vehicle PCB

To adapt to electrification, automotive PCBs are evolving toward High-Density Interconnect (HDI) and rigid-flex designs, reducing size and weight while improving heat dissipation and signal integrity.

Behind these innovations are advanced manufacturing processes. AI-driven quality control now verifies each PCB‘s reliability. Automated optical inspection (AOI) detects defects at the micron level.

As cars become software-defined platforms, new technologies emerge. Embedded trace substrates (ETS) enable chip-level integration. Substrate-like PCB (SLP) miniaturize parts and improve cooling. These features are vital for electric vehicle systems. Next-generation 5G-V2X connectivity demands even higher signal integrity. This progress pushes materials science and engineering forward.

Future PCBs will integrate more functional modules into unified boards. This supports centralized domain control architectures. New materials like ceramics improve heat resistance. These innovations make cars smarter and more reliable.