Application of PI Tape in Flexible PCB (Flex PCB)

Flexible PCB (Flex PCB) are now wildly used in many kinds of electronic products, while PI Tape is the main materials. Polyimide (PI) tape, a high-performance adhesive material, plays a critical role in the manufacturing and protection of Flexible PCB (Flex PCB). Its exceptional thermal stability, chemical resistance, and mechanical flexibility make it an indispensable component in modern electronics.

PI tape serves multiple functions in FPC applications. Primarily, it provides insulation and protection for delicate circuit components, especially in dynamic flexing areas such as hinge mechanisms in wearable devices. For instance, a leading smartwatch manufacturer successfully implemented a 25 μm thick PI tape with silicone adhesive to resolve reliability issues, achieving over 50,000 dynamic flex cycles with minimal conductivity loss. Its ability to withstand temperatures ranging from -269°C to +400°C ensures reliability during high-temperature processes like reflow soldering (up to 260°C), where it protects gold fingers from solder splatter and oxidation.

Moreover, PI tape’s chemical inertness shields circuits from corrosive solvents and acids during cleaning and etching processes. In automotive and aerospace applications, it insulates high-voltage components and battery tabs in electric vehicles, reducing short-circuit incidents by 85% and extending battery lifespan. The tape’s dielectric strength (≥4.5 kV) further prevents electrical failures in demanding environments.

Advanced variants, such as reinforced PI tapes with glass fiber or ceramic fillers, enhance mechanical durability for heavy-duty applications. Emerging innovations include nanostructured PI films with graphene or carbon nanotubes, which improve thermal conductivity and strength, supporting next-generation technologies like 5G antennas and flexible OLED displays.

In summary, PI tape’s unique properties—thermal resilience, flexibility, and electrical insulation—make it vital for ensuring the reliability and longevity of Flexible PCB (Flex PCB) across consumer electronics, automotive, and aerospace industries.

Advantages:

1. It has high temperature resistance, high strength of tensile, good chemical resistance and no residual glue. At the same time, it conforms to ROHS environmental protection halogen free.

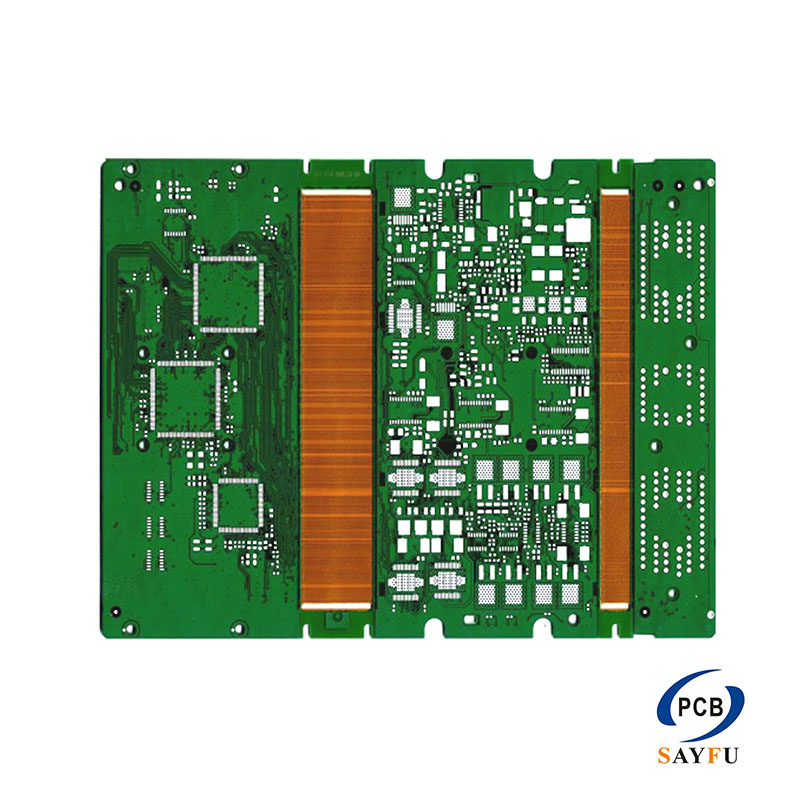

2.It is suitable for Flexible PCB (Flex PCB) wave soldering shielding, protecting gold finger and high-grade electrical insulation, motor insulation, and lithium battery positive and negative lug fixing.

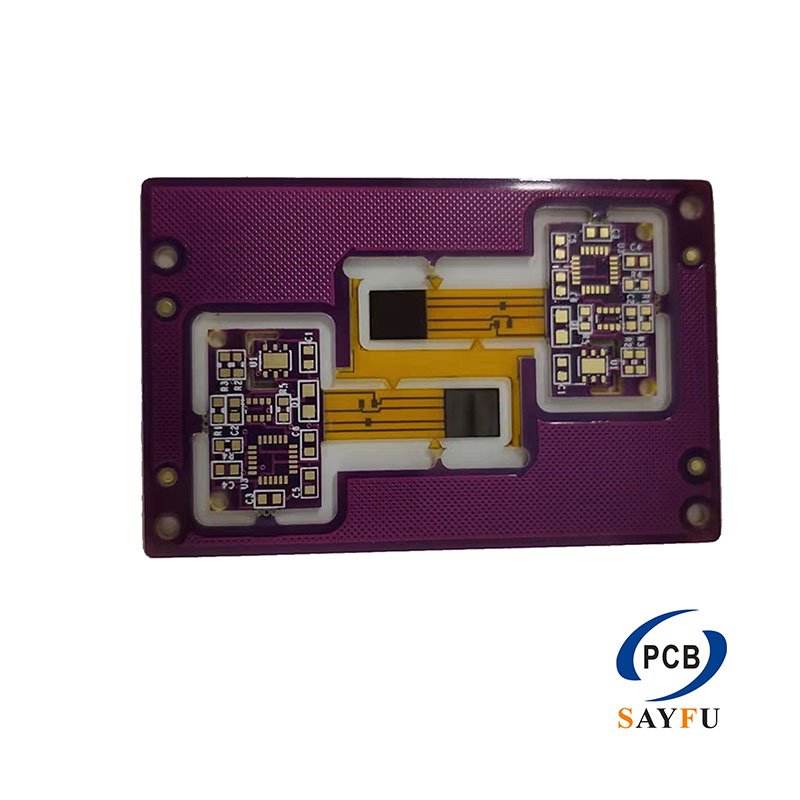

3.It is also suitable for rigid-flex pcb related production: improve yield and streamline process.