According to the statistics of the Taiwan rigid flex circuit board Association, in 2019, the rigid flex circuit board is one of the most powerful technology categories for Taiwanese PCB manufacturers.

With the low base, the second-generation AirPods in 2019 will contribute to this wave of growth. In addition, the increase in the utilization rate of advanced driver assistance system modules for vehicles has also made the combination of rigid-flex a key opportunity for some companies to enter the high-end automotive market. Looking to the future, as the types of consumer electronic products become more and more diversified, it is expected that the advantages in design will increase the market penetration rigid flex circuit board.

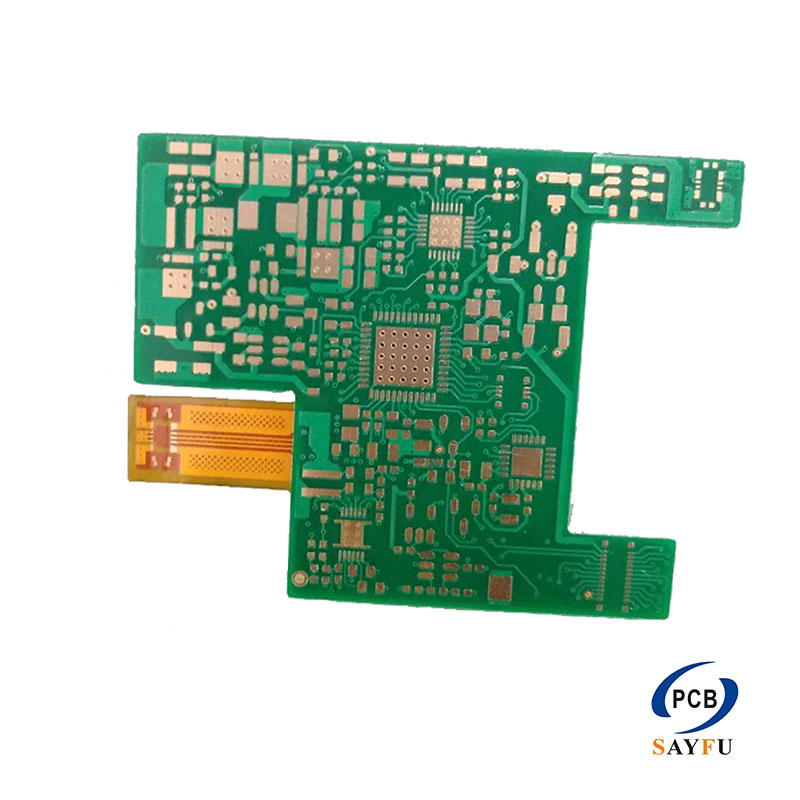

The fabrication of rigid flex circuit board (soft-hard bonded boards) presents several critical challenges due to material and process complexities.

First, thermal expansion mismatch between rigid (e.g., FR-4) and flexible materials (e.g., polyimide) induces stress, risking delamination or warpage during lamination and operation. Second, precise alignment is required for ultra-thin layers, as misalignment can cause short circuits or open circuits, especially in high-density designs. Third, adhesive control is crucial—excessive flow can contaminate circuits, while insufficient bonding leads to voids. Fourth, ultra-thin copper foils (≤3μm) face adhesion issues due to low surface roughness and thermal stress, demanding specialized treatments like plasma cleaning or micro-etching. Lastly, the lamination process requires optimized temperature/pressure profiles to balance resin flow and dimensional stability. Advanced techniques like vacuum lamination and laser drilling are essential to mitigate these issues.

Recent years ,Our SAYFU PCB have also been transforming to the development of such products, Sayfu has made great efforts to promote the progress of such projects and provided great support in terms of price and lead time .