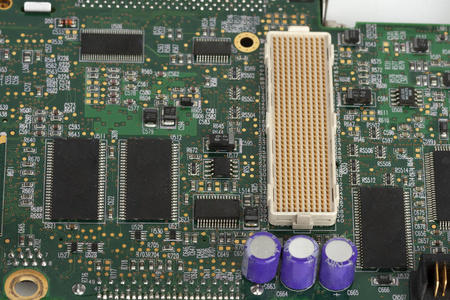

The Innovation and Transformation of PCB Industry is becoming one of the hot topics when the manufacturer are gathering. Such as all kinds of Forums, Industry Conferences and Communication Meetings. PCB, as the “Invisible Bone” of the electronics industry, is not so noticeable in common days. But it is the critical basement to connect all kinds of electronic components. Currently, PCB industry is suffering deep change on this blue earth. The resonance of technical innovation and market requirements promote the PCB industry to a higher level.

1. The PCB Industry Scale

At the same time, the PCB industry is expanding continuously. And according to the data analysis, the output value of global PCB industry has reached to about 80 billion US Dollars. China as the largest POO of PCB manufacturing, she contributes almost ½ of the PCB output globally. However, behind the growth in quantity lies a qualitative leap. The requirements of traditional multi-layer PCB is getting steady, while the demands for PCBs like HDI PCB, Flexible PCB, IC and other high-end PCB are now on a surging trend. Besides, the rapid development of smartphone, 5G communication, automotive electronics and IoT devices raises a higher demands on PCB precision, stability and its miniaturization. Meanwhile, the promotion of environmental friendly raw material and green manufacturing process affect the urgent need of global sustainable development deeply.

2. Technology Breakthrough

The Innovation and Transformation of PCB Industry and PCB technology breakthrough are becoming the core engine to drive the PCB industry to move forward. At this moment, PCB manufacturing technique has entered into a “Micron Era” with a trend of electronic devices moving towards lightweight and multifunctional development. Besides, the line space and width are being shrunk continuously with the innovative application of laser drilling, stacked hole process and advanced pattern & platting technology. The signal transformation speed and stability are improved greatly, too.

3. The Adjustment of Industrial Chain Pattern

The industrial chain landscape is also undergoing dynamic adjustments. The Sino-US trade friction and the reorganization of regional supply chain make the Chinese PCB manufacturers increase R&D efforts. This order them to expand into upstream materials and equipment fields to reduce external dependence. The leading PCB enterprises, such as Shennan Circuits Company Limited and WUS Printed Circuit have already secured a foothold in the high value-added product market. And gradually achieve import substitution in high-end substrate and other fields.

4. The Challenges Still Exist

Even through we achieved great achievements during the past years. We have to acknowledge that there are challenges we are facing.

Fluctuations in raw material prices, rising environmental compliance costs, and a shortage of high-end talent are constraining the industry’s development. In the future, with the rise of artificial intelligence, new energy vehicles, and high-end equipment manufacturing, the PCB industry will further transition toward higher technological content and greater reliability. Only by persistently focusing on technological innovation and industrial chain collaboration can Chinese enterprises consolidate their advantages in global competition. And truly achieve the leap from a “Manufacturing Powerhouse” to a “Intelligent Manufacturing Powerhouse.”

This intricate web that carries modern technology continues to weave more complex and powerful connections, quietly shaping the future electronic world.