Current Market Dynamics and Drivers

HDI boards are playing a pivotal role in the transformation of China’s electronics market. This expansion is fueled by relentless consumer demand for advanced electronics. The unique capabilities of HDI boards enable smaller and more powerful devices. Consequently, production volumes for these sophisticated boards are rising significantly. A robust and competitive marketplace has emerged around this technology. Both domestic and international demand continues to strengthen this sector.

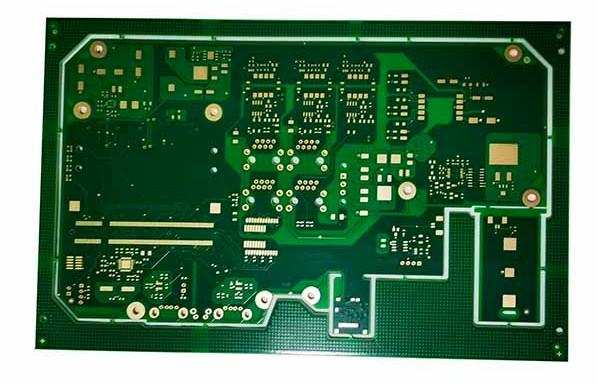

Technological Advancements and HDI Boards

Innovation is the key driver in this sector. The evolution of HDI boards allows for significantly higher circuitry density. This is essential for the miniaturization of modern gadgets. Chinese manufacturers are rapidly advancing their technical expertise. They are now producing more reliable and efficient boards. This directly enhances the performance of final products like smartphones. The complexity of these interconnect solutions continues to increase. Research and development are focused on pushing the boundaries of this technology even further.

Supply Chain and Manufacturing Ecosystem

A mature supply chain is vital for sustained growth. The production of advanced circuit boards requires strong material support. China is successfully building a comprehensive domestic ecosystem. This development reduces historical dependencies on foreign imports. Major industrial regions have become specialized hubs. These clusters optimize logistics and foster collaboration. The entire industry chain is becoming more integrated and efficient. This consolidation strengthens China’s position as a global manufacturing leader for electronics.

Future Outlook and Emerging Challenges

The future prospects for this technology in China are highly promising. Next-generation applications like 5G and the Internet of Things will be major consumers. These fields represent significant long-term growth opportunities. However, the market landscape is also becoming more challenging. Intense competition pressures companies to continuously innovate. Environmental and sustainability concerns are also gaining prominence. Manufacturers are increasingly adopting greener production practices. The journey ahead will require constant adaptation and technological refinement.