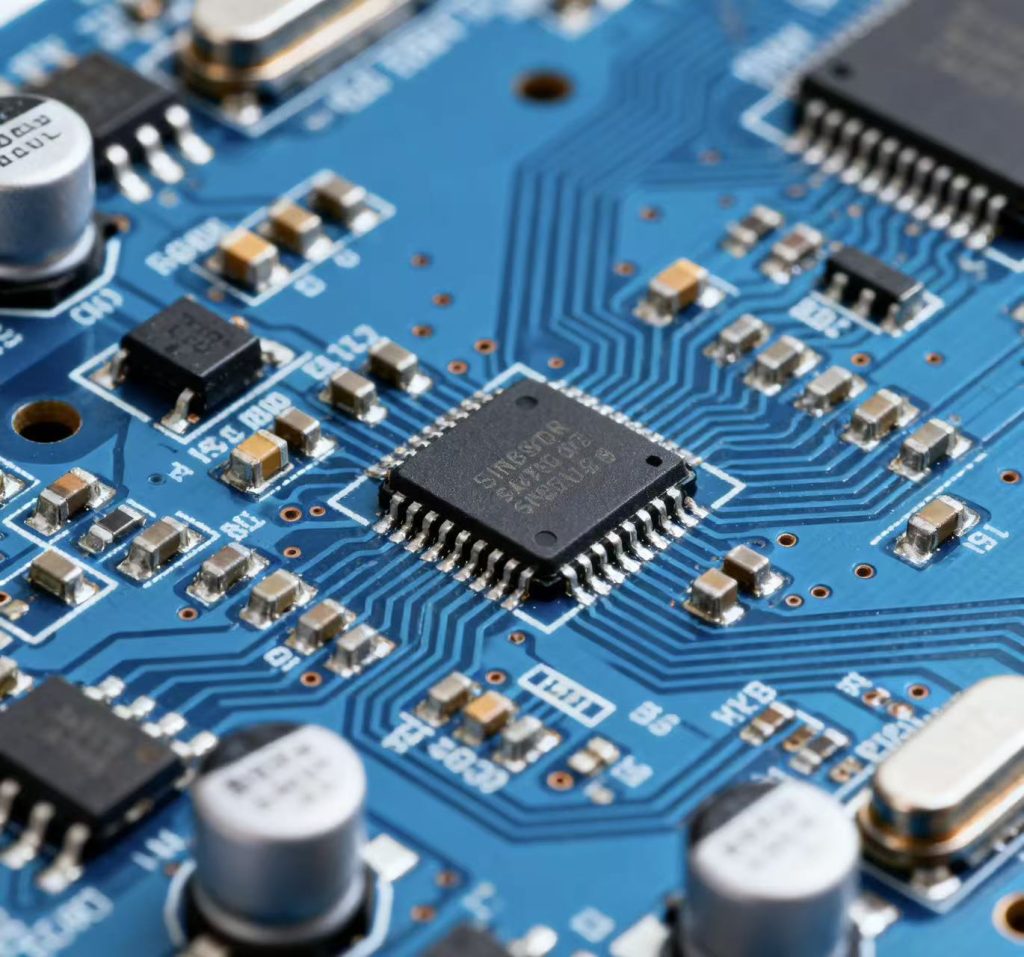

A Sensor PCB is a printed circuit board specifically designed to integrate and support sensor components. It combines sensitive sensors (such as temperature, pressure, motion, or optical sensors) with signal processing circuits on a compact platform. Sensor PCB is widely used in automotive, medical, industrial, and consumer electronics sectors, capable of real-time detection and transmission of environmental data, enhancing the intelligence and automation levels of equipment. Sensor PCBs not only provide mechanical stability and electrical connections but also minimize interference through optimized layout, ensuring high accuracy and reliability. With the development of the Internet of Things and intelligent technologies, Sensor PCBs have become the core component of modern electronic systems, promoting the popularization of innovative applications.

Design requirements of the Sensor PCB

The design of the Sensor PCB must meet strict standards to ensure the accuracy and stability of the sensor performance.

Firstly, layout optimization is crucial: sensor components should be placed away from noise sources (such as power supplies or high-frequency circuits), and short paths should be used to connect the signal processing part to reduce signal attenuation and electromagnetic interference.

Secondly, material selection needs to consider environmental factors, such as using heat-resistant and moisture-proof substrates (such as FR-4 or flexible PCB materials) in high-temperature or humid environments.

Additionally, impedance matching and grounding design must be precise to maintain signal integrity and prevent data distortion. Finally, the design should support calibration and debugging functions. These requirements collectively ensure the reliability of the Sensor PCB in high-sensitivity applications and extend its service life.

Manufacturing and testing standards

When manufacturing Sensor PCB, process control is of utmost importance, including the use of high-precision etching and welding techniques to ensure the accuracy of the fine lines and sensor connections. The testing phase involves multiple checks, such as automatic optical inspection (AOI) and functional testing, to verify the response and circuit performance of the sensors. Environmental tests (such as temperature cycling and vibration tests) are also essential to assess the PCB’s durability under extreme conditions. These standards help manufacturers deliver high-quality products that meet industry standards.