The Critical Role of Surface Mount (SMT) PCB Assembly Manufacturer in Autonomous Driving Technology is recognized fast in recent years.

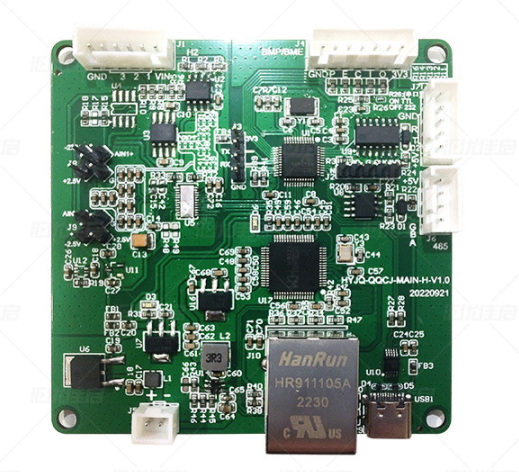

Printed Circuit Boards (PCBs) serve as the backbone of autonomous driving systems, enabling the integration, signal processing, and reliable operation of complex electronic components. As autonomous vehicles rely on intricate sensor networks, high-performance computing units, and real-time data transmission, Surface Mount (SMT) PCB Assembly Manufacturer have evolved to meet stringent technical demands, particularly through multi-layer designs and advanced manufacturing processes.

Key Requirements for Autonomous Vehicle PCBs

Autonomous driving imposes unique challenges on PCBs, driven by the need for safety, reliability, and performance:

High Reliability: PCBs must withstand extreme temperatures and prolonged operation without failure, ensuring consistent performance in diverse environments.

Signal Integrity: They facilitate high-speed data transmission between sensors (e.g., LiDAR, cameras) and control units, critical for real-time environmental perception.

Anti-Interference: Advanced electromagnetic shielding minimizes interference, safeguarding sensitive electronics from external signals.

Thermal Management: Efficient heat dissipation prevents overheating in high-power systems, maintaining stability during extended use.

Multi-layer PCBs: The Core of Autonomous Systems

Multi-layer PCBs are indispensable in autonomous vehicles due to their superior functionality:

Signal Processing Hub: They integrate microprocessors, memory modules, and communication interfaces, acting as the “brain” for data analysis and decision-making.

Sensor Integration: By consolidating radar, camera, and GPS modules, multi-layer PCBs enable seamless data flow, supporting rapid response to dynamic road conditions.

Space Efficiency: Stacked layers reduce physical size while increasing circuit density, accommodating the compact design requirements of modern vehicles.

Industry Applications and Case Studies of Surface Mount (SMT) PCB Assembly Manufacturer

Surface Mount (SMT) PCB Assembly Manufacturer like Sayfu Multilayer Circuits Co., Ltd exemplify how PCB solutions address autonomous driving needs:

Material Selection: High-quality substrates and copper-clad laminates enhance temperature resistance and signal transmission efficiency.

Certifications and Quality Control: Compliance with ISO 9001 and ISO 14001 standards ensures product reliability, as demonstrated by partnerships with leading autonomous vehicle developers.

Rapid Prototyping: Agile manufacturing capabilities support iterative design processes, accelerating the development of next-generation autonomous systems.

Future Trends

As autonomous technology advances, PCBs will continue to evolve, with innovations in flexible PCBs, embedded sensors, and AI-optimized layouts. These developments will further enhance system integration, reduce latency, and support the transition to fully autonomous mobility.

In summary, PCBs are foundational to autonomous driving, enabling the precision, reliability, and performance required for safe and efficient transportation. Their role will only grow as the industry moves toward higher levels of automation.