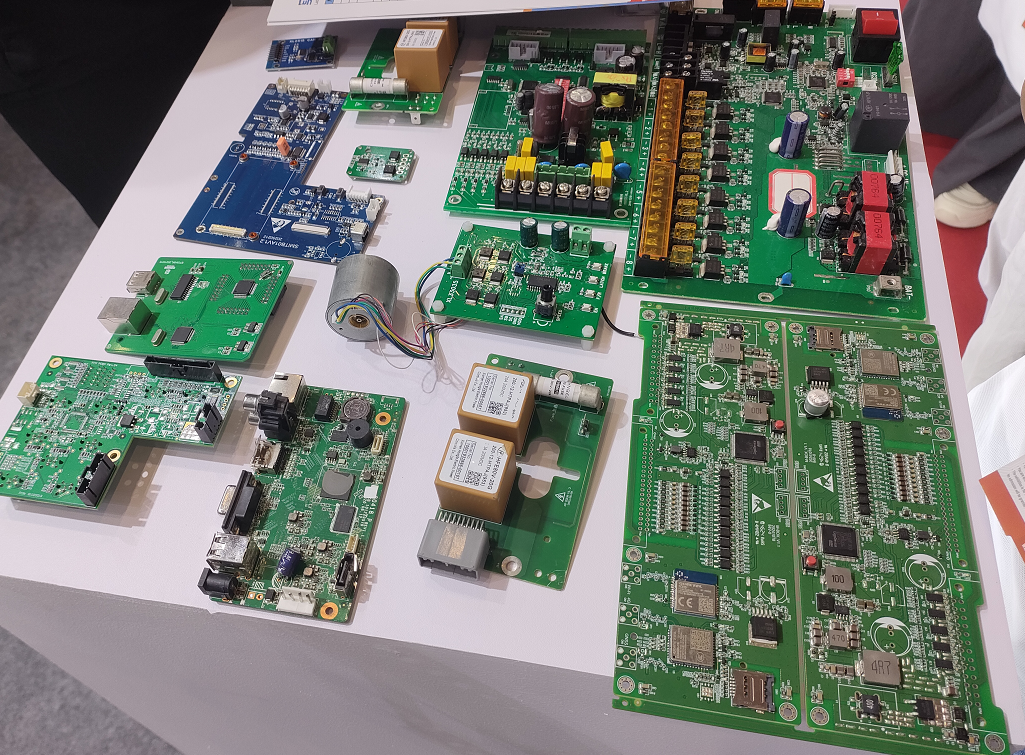

SMT PCB Assembly Manufacturers play a pivotal role in modern electronics production, enabling the creation of compact, high-performance devices that power our digital world.

These specialized facilities combine advanced machinery, skilled technicians, and rigorous quality control to transform printed circuit boards into functional electronic components.

The SMT PCB Assembly Manufacturers Advantage

SMT assembly offers several key benefits over traditional through-hole methods:

- Miniaturization: Allows for smaller device sizes

- Higher component density: Enables more complex circuits

- Automation: Supports faster production cycles

- Cost efficiency: Reduces material and labor expenses

The SMT PCB Assembly Manufacturers Process

- Solder Paste Application: A stencil applies precise amounts of solder paste to board pads

- Component Placement: High-speed pick-and-place machines accurately position surface-mount devices

- Reflow Soldering: Boards pass through ovens to melt solder and create permanent connections

- Inspection: Automated optical inspection (AOI) and X-ray systems verify component placement and solder joints

- Testing: Functional testing ensures complete circuit operation

Quality Control Measures

Reputable SMT manufacturers implement comprehensive quality assurance protocols:

- Statistical process control (SPC) monitoring

- First article inspection (FAI)

- In-circuit testing (ICT)

- Environmental testing for reliability

- Traceability systems for component sourcing

Industry Applications

SMT PCB assembly serves diverse sectors:

- Consumer electronics: Smartphones, wearables, smart home devices

- Industrial equipment: Control systems, sensors, automation

- Medical devices: Diagnostic equipment, patient monitoring

- Automotive: Infotainment systems, advanced driver assistance

- Aerospace: Avionics, navigation systems

Choosing a Manufacturer

Selecting the right SMT PCB assembly partner requires consideration of:

- Capabilities: Board size limits, component types, layer count

- Quality certifications: ISO 9001, IPC standards compliance

- Volume capacity: Prototyping vs. mass production needs

- Geographic location: Supply chain logistics

- Technical support: Design for manufacturability (DFM) assistance

As technology continues to evolve, SMT PCB assembly manufacturers remain at the forefront of electronic innovation, driving advancements in device performance, reliability, and miniaturization across industries.

Choosing a good PCBA supplier is extremely important. It is the key to ensuring efficiency and quality. If you have any needs, pls feel free to contact us at any time.