Shenzhen PCB Assembly Factory is getting more and more but with network of 5G higher and higher requirements, are we really ready accepting high demand of high precise PCB&PCBA?

Communication has become an indispensable tool for people to communicate with each other. With the development of the times, in just a few years, we have upgraded from 2G network to the current 5G.

With the development of technology, the production efficiency and precision processing characteristics of advanced laser processing technology determine the importance of other positions in mobile phone manufacturing. The large-scale application of laser processing technology in mobile phone manufacturing has also brought laser equipment providers. HDI circuits are getting more and more complicated in cater of cell phone capacity demand.

Great economic benefits. Due to the high speed and low latency of 5G networks, new requirements for compound semiconductor performance will be put forward. Mobile phone materials and manufacturing processes will change to adapt to 5G new technologies. Mobile phones are becoming thinner and lighter, screens are getting bigger and bigger, and cameras are coming. The clearer it will still be the mainstream development direction, the future internal components of mobile phones will become smaller and smaller, which requires the development of our Shenzhen PCB Assembly Factory to keep pace with the times and keep in mind technological innovation.

Shenzhen PCB Assembly Factory is Fighting for Huawei Orders

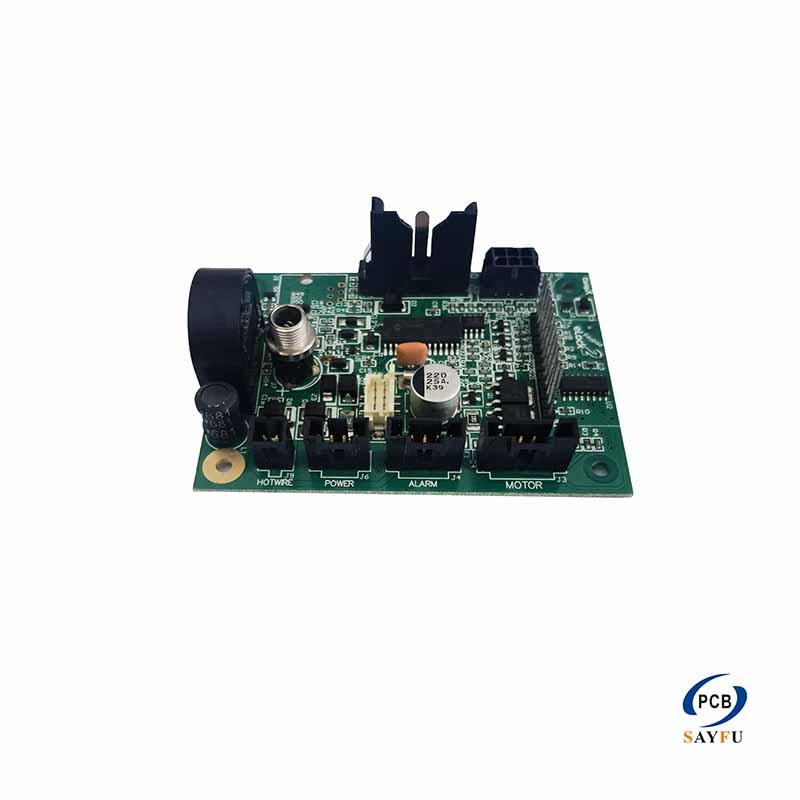

Precision SMT (Surface Mount Technology) plays a pivotal role in the manufacturing of modern smartphone motherboards. It enables the dense, reliable assembly of microscopic components essential for advanced functionality. This is exemplified in Huawei’s flagship products, such as the Mate60 series.

High-precision SMT processes handled by Shenzhen PCB Assembly Factory, particularly utilizing advanced techniques like high-speed dual-track placement lines and PoP (Package on Package) stacking, allow for the efficient and accurate mounting of ultra-miniaturized components, including resistors (down to sizes like 01005), capacitors, and complex ICs, onto densely packed PCBs. These technologies enable sub-millimeter placement accuracy, crucial for fitting powerful circuitry into slim devices .

For Huawei, this capability translates directly into mass production scalability and performance consistency. Manufacturers like Guanghong Sayfu, a key partner, leverage these sophisticated SMT lines to meet the massive production demands of Huawei phones (e.g., targeting tens of millions of units annually), ensuring each device meets stringent quality standards. The precision minimizes defects, enhances electrical performance stability, and underpins the reliability expected in high-end smartphones, making SMT an indispensable foundation for Huawei’s cutting-edge mobile technology.