Rigid multilayer PCB manufacturing in Shenzhen leverages a complete supply chain, acting as a global core and supporting 5G,and new energy vehicle and industrial equipment needs.

The Pearl River Delta has a strong electronics industry. Shenzhen uses this plus full supply chains (from raw materials to checking finished products). So it becomes a top global place for rigid multilayer PCB making. This kind of PCB has dense circuits and works well in different environments. It is key for 5G towers, new energy car controls and industrial PLC machines. Now, Shenzhen makes over 40% of China’s rigid multilayer PCBs. It has a fast and well-connected industry system.

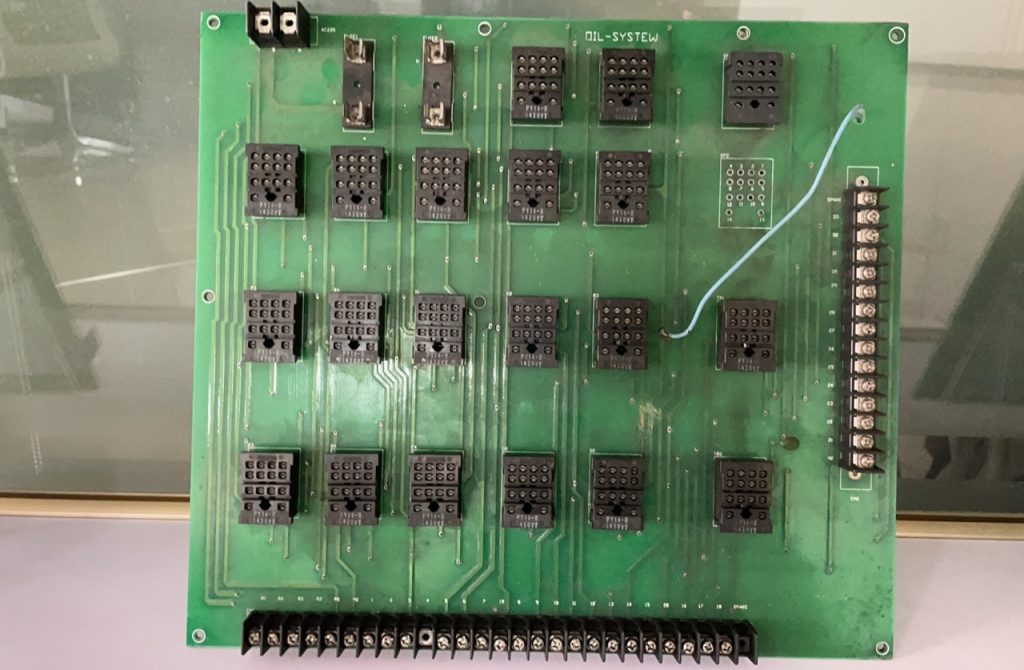

Rigid Multilayer PCB manufacturing : How It’s Made and Its Strengths

Rigid Multilayer PCB manufacturing focuses on two things: good links between layers and precise circuits. First, etch copper boards to make inner patterns. Use AOI (a tool to check) to find and fix flaws. Then treat inner boards to make them stick better. Press layers together as designed—at 180-200℃ and 30-50kg/cm². Next, drill holes and add copper to connect layers. Tech-wise, layer alignment errors stay under 0.1mm. Line width and space reach 3mil/3mil. Use gold coating, OSP and X-ray checks. So over 98% of products work well. It fits scenes needing high reliability.

Shenzhen’s Local Supply Chain Helps a Lot

Shenzhen has a “1-hour supply chain”. Specifically, it covers key things: copper boards, etching inks and laser drills. Firstly, this makes buying materials and fixing machines 50% faster. Additionally, it also cuts production time to 7-10 days. Costs go down a lot. Furthermore, with this help, Sayfu keeps improving tech. It does better in HDI (dense links) and thick-copper PCBs. Its products meet local high-end needs. They also sell to electronic firms in Europe and America. This makes Shenzhen more competitive worldwide.