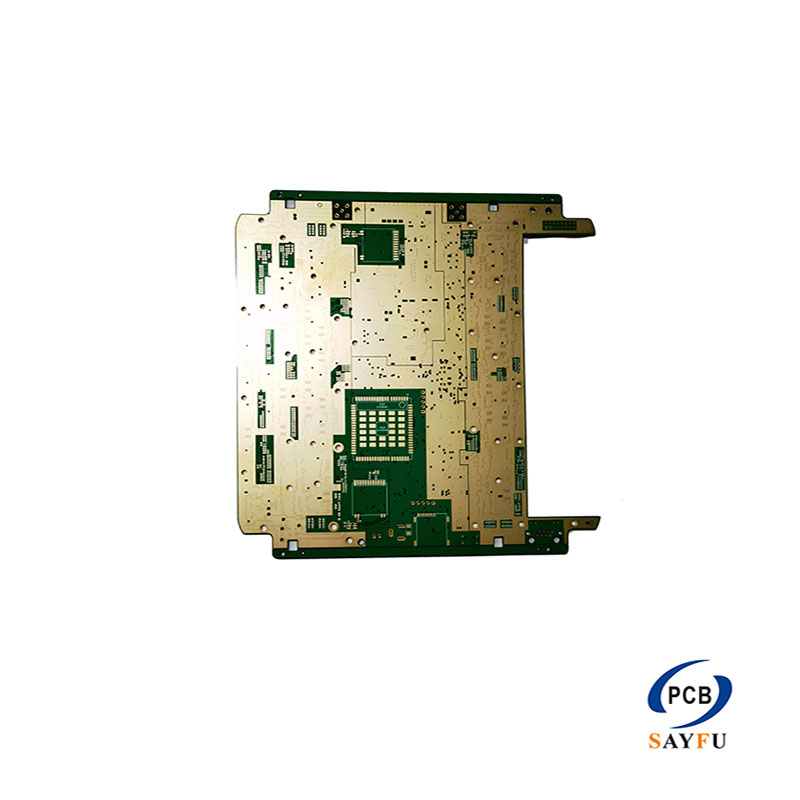

RF Microwave PCB manufacturer refers to a company that specializes in designing and producing printed circuit boards (PCBs) for circuits operating at radio frequency (RF) and microwave frequencies. RF generally refers to electromagnetic waves with frequencies ranging from 300 kHz to 300 GHz, while microwaves cover higher frequency bands from 300 MHz to 300 GHz. Unlike ordinary PCBs that handle low-frequency digital signals, RF Microwave PCBs need to transmit and process high-frequency analog signals, which makes their design and manufacturing process extremely complex and precise. Such manufacturers possess specialized engineering techniques, special materials, and advanced equipment, capable of addressing the unique challenges posed by high-frequency applications, such as signal integrity, impedance control, and dielectric loss, etc.

Reasons for Choosing an RF Microwave PCB Manufacturer

Choosing a professional RF Microwave PCB manufacturer is of utmost importance. Firstly, they are proficient in the selection of specialized substrates, such as Rogers and Taconic, which have low loss factors (Df) and stable dielectric constants (Dk). These materials can significantly reduce signal loss and distortion during transmission. Secondly, professional manufacturers have the ability to precisely control the characteristic impedance. Through precise etching and laminating techniques, they ensure that the tolerance of trace width and spacing is extremely small, thus matching the impedance requirements of the system design and avoiding signal reflection. These are indispensable for ensuring the integrity and connection reliability of microwave signals. Finally, we usually equip advanced testing equipment such as vector network analyzers to verify whether their high-frequency performance meets the standards. This is a core value that ordinary PCB manufacturers cannot provide.

The core technical considerations of high-frequency circuit boards

In the design and manufacturing of RF Microwave PCBs, multiple core technical considerations are involved. Impedance control is the primary task, which requires precise calculation of the geometrical shape of the traces and the thickness of the dielectric material to achieve the target impedance. Secondly, signal integrity management is of vital importance, involving the reduction of crosstalk, ensuring a good grounding layer design, and using simulation software for pre-layout prediction and optimization. Additionally, thermal performance is also a major challenge, as high-frequency signals generate more heat, which requires PCB materials to have good thermal conductivity. Professional manufacturers integrate these technical considerations and work closely with the design teams of their clients to ultimately deliver high-performance, compliant with strict specification requirements, high-frequency circuit boards, which are widely used in key fields such as aerospace, military radar, 5G communication, and automotive radar.