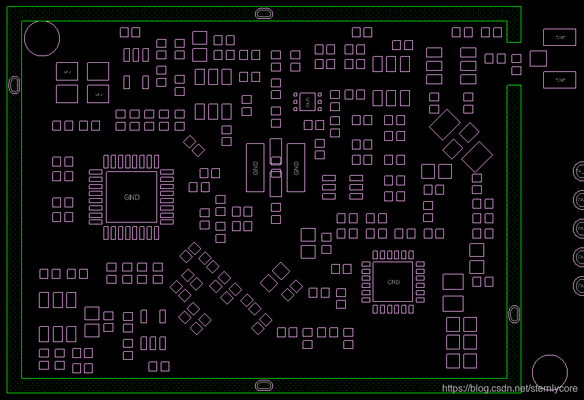

PWB Board design is the very beginning of an electronic product, while opening widows is extremely important.

Below shows some reasons:

1.Through hole opening, when the electronic component is in wave soldering, spraying tin on the inner wall of the hole will increase the hole’s current capacity.

2.In the factory processing, if the copper sinking process is not completed, there will be some holes conducting Defective, tinned through-hole windows are opened, and it is sufficient to insert metal feet up and down for welding during maintenance, which is more convenient for maintenance.

3.Single-sided and double-sided pcb have such requirements, and multi-layer boards generally do not require ordinary windows to open through holes.

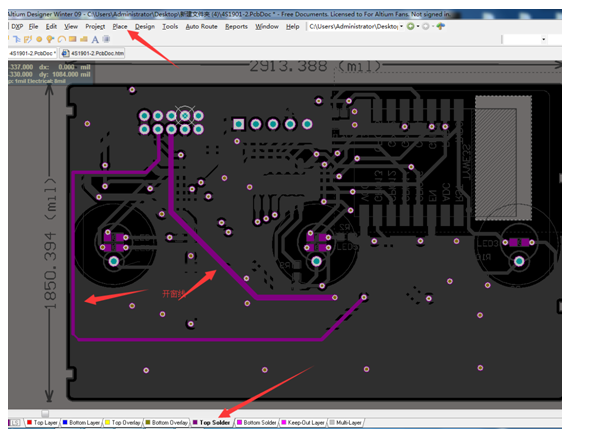

The Importance of PWB Board Windowing in Design

PWB Board windowing, a critical technique in printed circuit board design, involves removing solder mask to expose copper traces or pads. This process significantly impacts circuit performance and manufacturing efficiency.

Key Benefits:

Enhanced Signal Integrity

Windowing optimizes impedance matching by adjusting trace width, reducing resistance/inductance fluctuations, and minimizing signal reflection, thus improving high-speed data transmission quality.

Improved Thermal Management

Exposed copper areas facilitate heat dissipation, lowering operating temperatures and boosting long-term reliability, especially in power electronics.

EMC Performance

By reducing crosstalk and electromagnetic interference (EMI), windowing enhances electromagnetic compatibility (EMC), critical for high-frequency circuits.

Manufacturing Flexibility

It enables precise soldering, supports current handling through thicker copper traces, and simplifies post-assembly modifications.

Considerations for PWB Board design opening:

While windowing improves electrical performance, it may reduce mechanical strength and increase production costs due to additional processing steps. Balancing these factors ensures optimal design outcomes.

In summary, PWB Board windowing is indispensable for achieving robust signal transmission, thermal efficiency, and manufacturing adaptability in modern electronics.

Guangdong Sayfu is not only a PWB Board manufacturer but also an experienced designing service provider. If you want to find an one turkey PCB&PCBA partner, please contact with us. Our sales team is there waiting for your inquiry.