1. Defining the Core Function of Power Printed Circuit Board

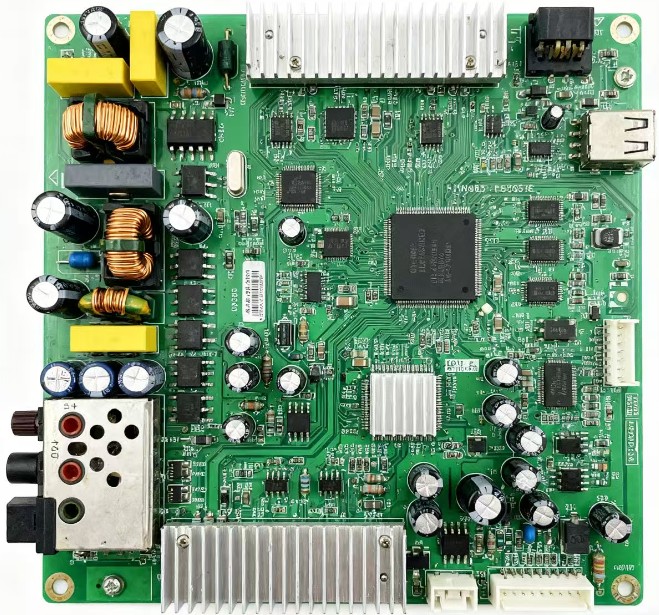

Power Printed Circuit Board refers to a specialized type of circuit board designed primarily to manage, distribute, and control significant electrical power. Rather than just delicate digital signals. Standard PCBs focus on signal integrity. However, a Power PCB must handle high currents and voltages. Its key goals are minimal power loss and efficient heat dissipation. This critical distinction makes its design and material selection vital for overall system safety and performance.

2. Key Design and Material Considerations

The design philosophy of a Power Printed Circuit Board is fundamentally different. Key considerations include the use of thicker copper layers, often exceeding 2 ounces per square foot, to carry high currents without overheating. Thermal management is paramount. Therefore, a well-designed Power PWB will incorporate large copper planes, thermal vias, and sometimes even integrate metal cores (MCPCB). The layout is also optimized to minimize loop inductance and ensure stable power delivery to components like motors and power converters.

3. Power Printed Circuit Board applications in Modern Technology

The applications for a robust Power PCB are vast and critical. They form the foundation of power supplies, industrial motor drives, automotive control systems, and renewable energy inverters. In an electric vehicle, for instance, a Power PCB is responsible for distributing power from the battery to various subsystems, a task that demands extreme precision and durability. The failure of a standard PCB in such an application would be catastrophic. This potential risk underscores the vital role of a properly engineered Power PCB.

4. Conclusion: Enabling a Powerful Future

In conclusion, while often operating behind the scenes, the Power Printed Circuit Board is an engineering marvel that enables the high-power applications that define our modern world. Its design is a careful balance of electrical, thermal, and mechanical engineering principles. As devices continue to demand more power in smaller packages, the innovation and importance of the Power PWB will only continue to grow.