PCB Separation and Shaping is a common requirement for makers and engineers during prototyping or repair. Unlike cutting ordinary materials, PCB separation requires precision to avoid damaging delicate copper traces and components. Successful cutting depends on selecting the right technique and tools for the task, balancing precision, ease of use, and board integrity

1.Scoring and Snapping for Straight Lines

The simplest and most accessible method for cutting straight lines is scoring and snapping. Using a utility knife or a dedicated scoring tool, you make several deep, parallel scores along a straight edge on both sides of the fiberglass board. The board is then aligned with the edge of a table, and firm, even pressure is applied to snap it along the scored line. This technique is cost-effective and generates no dust, but it is only suitable for creating simple, straight breaks and requires a steady hand to score accurately.

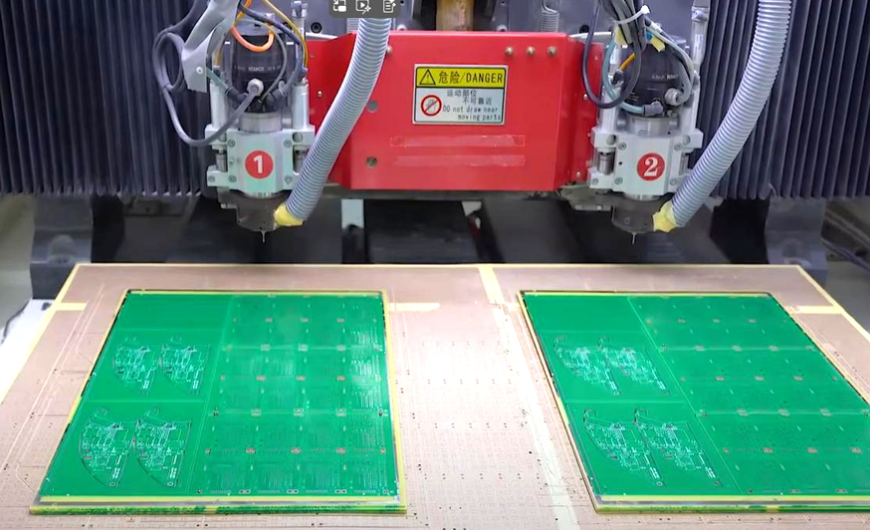

2.Using a Guillotine Shear for Clean PCB Separation and Shaping

For frequent work or cleaner, more consistent straight cuts, a PCB guillotine shear is the ideal tool. It operates like a paper cutter, applying strong, even pressure to cleanly shear the board along a predetermined line. This method is fast, produces no harmful dust, and minimizes stress on the board material compared to snapping. While guillotines are excellent for their specific purpose, they are a dedicated tool with a higher cost and are not suitable for cutting complex shapes or already populated boards.

3.Precision Cutting with a Rotary Tool

For intricate cuts, curves, or modifying a board that already has components installed, a rotary tool (such as a Dremel) equipped with a reinforced fiberglass or abrasive cutting wheel is the most versatile option. This method offers unparalleled freedom to cut any shape. However, it generates a significant amount of fiberglass dust, which is hazardous to inhale. Therefore, it is imperative to wear a respirator and eye protection, and to use dust extraction if possible. The key is to make slow, steady passes to ensure control and prevent the tool from grabbing.