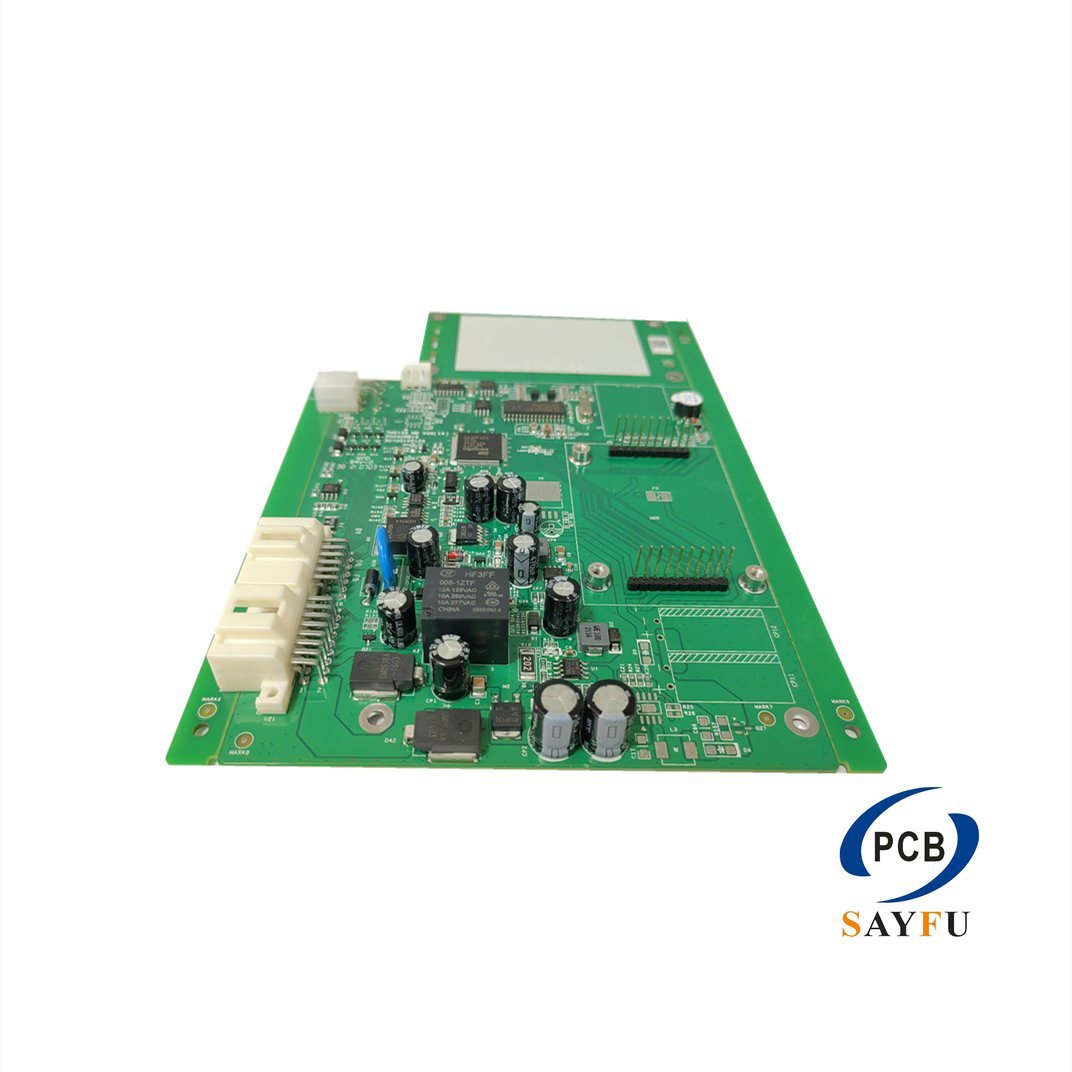

PCB Assembly with advanced SMT Technology- 6 layers Printed circuit board

Images

General Specification:

Layer No: 6 layer

Panel size/mm: 135mm*135mm

Material: FR4

Finished Thickess:1.6mm

Finished Copper: 35um

Surface treatment: ENIG

Soldermask: Green

Silkscreen:White

A surface mount technology (SMT Technology) stencil may also be called a PCB sentil, solder paste stencil, or laser stencil.

A SMT Stencil’s main purpose is to simply transfer the solder paste to a bare circuit board.

A stainless steel foil is laser cut to create an opening for each surface mount device on the board.

Once the printed circuit board (PCB) stencil is properly aligned with the top of the board, the solder paste is applied over the openings (in a single pass, with a metal squeegee).

When the stainless steel foil detaches from the board, solder paste remains, ready for the manufacture of the surface-mount device (SMD). In contrast to manual soldering procedures, this process ensures consistency and saves time.

Sayfu provide One stop turnkey partial PCBA. We have 6 sets reflow soldering machine for SMT and 2sets wave soldering machine for DIP. we also have set up small branch for component sourcing which save our customer valuable time and transportation fee.

PCBA Prototype Manufacturer Sayfu Enterprise culture

SAYFU quick turn prototype PCB assembly – Certification of high quality PCB international quality systems

The certification of international quality systems including UL E511658, ISO9001, ISO14001, IATF16949:2016

Part of SMT technology shops test machines