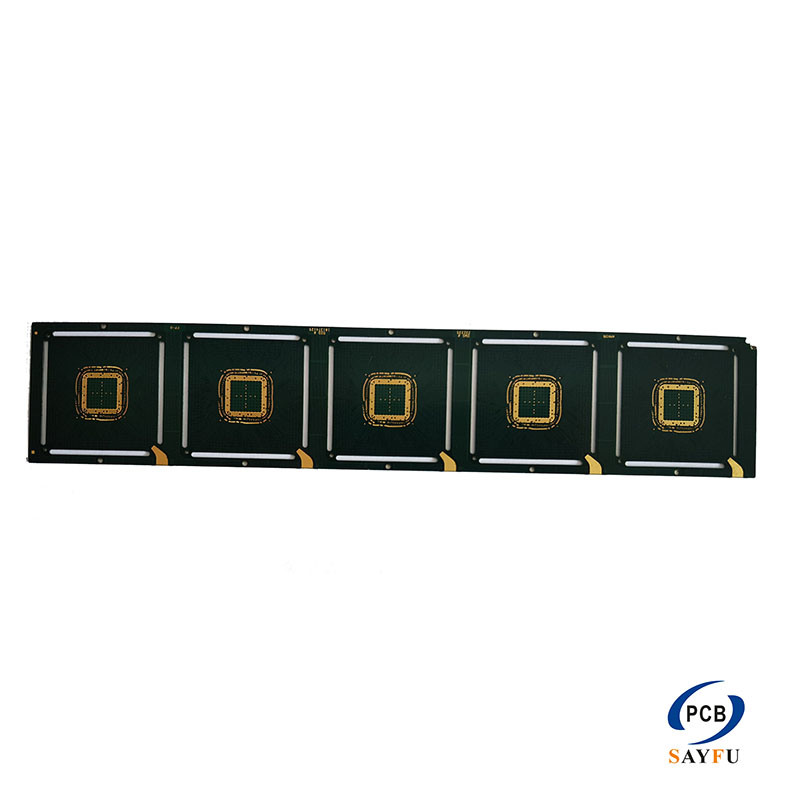

FC-CSP(Flip Chip-CSP)

Images

General Specification:

Number of layers: 2/4 layers

Structural features: There are many blind hole filling structures. The electrical connection design of the chip area includes SOP (Sold On Pad) or BOL (Bump On Line) design.

Size: 88mm~1214mm

Board thickness: 0.2~0.4mm

Line width/line distance: 25/25~50/50 um

Bump Pitch: 150~200um

Surface treatment: OSP

Special process: VOP

DEFINE

Flip Chip-CSP pcb board. FC (Flip Chip) is a type of package by flipping chip, featuring low signal interference, low circuit loss, well-performed performance and effective thermal dissipation.

APPLICATION

Smartphone processor

PC microprocessor/controller

Video/audio processor

IC substrate PCBs are mainly applied on electronic products with light weight, thinness and advancing functions, such as smart phones, laptop, tablet PC and network in fields of telecommunications, medical care, industrial control, aerospace and military.

Rigid PCBs have followed through a series of innovations from multilayer PCB, traditional HDI PCBs, SLP (substrate-like PCB) to IC substrate PCBs. SLP is just a type of rigid PCBs with similar fabrication process approximately semiconductor scale.

IC substrate is a type of base board used to package bare IC (integrate circuit) chip. Connecting chip and circuit board, IC belongs to an intermediate product with the following functions:

• it captures semiconductor IC chip;

• there’s routing inside to connect chip and PCB;

• it can protect, reinforce and support IC chip, providing thermal dissipation tunnel.

Sayfu has been gradually growing up to a company that can fabricate IC Substrate. We are focuse on quality, cost, service, and experience continual development. If you have any ICS-projects, send us freely, we can quote to you early. Cantact eamil: [email protected]. A special circuit board for chip packaging. Similar to the traditional rigid PCB processing technology. But the smaller in size, thinner than PCB. ICS denser through holes, and finer than the traditional rigid PCB.