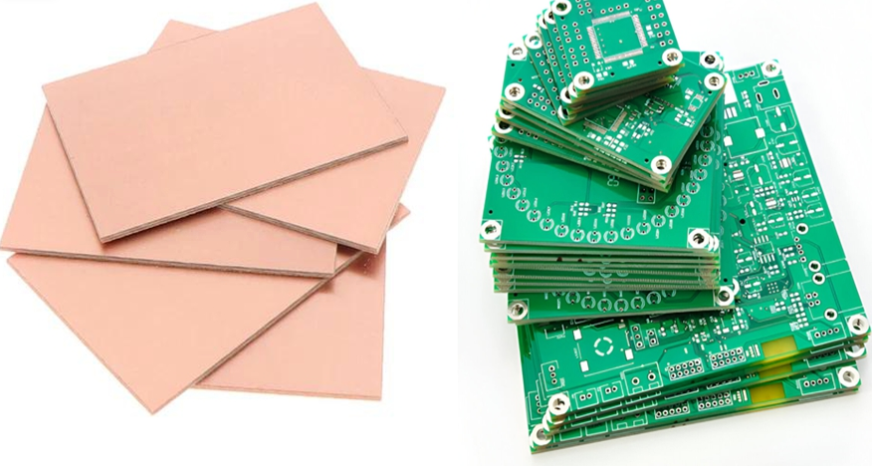

High-Frequency PCB Materials TU-933

PCB Materials TU-933 is a high-performance substrate for high-frequency circuits. It has a very low dielectric constant and loss factor. Therefore, it ensures excellent signal integrity. Its dielectric constant remains stable at 2.33±0.02. This makes it ideal for millimeter-wave applications. Furthermore, it maintains stable electrical performance over a wide bandwidth.

High-Temperature Material TU-883SP

TU-933+ is a high-performance substrate for high-frequency circuits. It has a very low dielectric constant and loss factor. Therefore, it ensures excellent signal integrity. Its dielectric constant remains stable at 2.33±0.02. This makes it ideal for millimeter-wave applications. Furthermore, it maintains stable electrical performance over a wide bandwidth.

High-Reliability Material TU-768

TU-768 offers superior resistance to ion migration. It passes stringent CAF testing for stability. Thus, it performs reliably in harsh humid environments. Its volume resistivity reaches 10^8 MΩ·cm. Moreover, it exhibits excellent arc resistance for automotive electronics.

Specialty Application Material EM-370Z

EM-370Z is a composite material for special circuits. It uses a unique filler formulation for thermal conductivity. Consequently, its thermal conductivity reaches 1.5 W/m·K. It also meets UL94 V-0 flame retardancy standards. Additionally, its mechanical strength is 40% higher than standard FR-

Material Selection and Processing

Material selection requires balancing multiple performance requirements. Meanwhile, processing parameters need corresponding adjustments. So, thorough process verification is essential before mass production.

These four specialty materials provide tailored solutions for various applications. Engineers must choose the most suitable material based on specific requirements. Ultimately, this ensures the final product’s reliability and stability in its operating environment.

Future Development Trends PCB Materials TU-933

The development of PCB materials continues to advance. New formulations will further improve thermal and electrical properties. Consequently, they will support next-generation communication and computing technologies. Additionally, environmental requirements will drive the development of greener materials.These materials will enable higher power density designs. They will also support flexible and rigid-flex applications. Therefore, they are crucial for future electronics innovation.