The Development History of Turnkey PCB Assembly in Taiwan

Turnkey PCB Assembly is a service including PCB Design,PCB fabrication, SMT, TESTING and BOX building. In thise artical, we will tell the history of PCBA developing in Taiwan.

Introduction

Taiwan’s rise as a global leader in the Printed Circuit Board (PCB) industry has significantly influenced the evolution of Turnkey PCB Assembly services on the island. This integrated approach—which encompasses design, procurement, fabrication, assembly, and testing—has matured alongside Taiwan’s broader electronics manufacturing ecosystem, driven by technological innovation, global supply chain dynamics, and strategic adaptations to market demands.

History

The foundation was laid in the 1980s–2000s, when Taiwan emerged as a key hub for electronics manufacturing, particularly as global PCB production shifted from the U.S. and Japan to Asia. Taiwanese manufacturers, supported by a robust local supply chain for materials like copper-clad laminates and substrates, began offering end-to-end solutions to international clients, including major brands like Apple. This period saw the growth of companies such as Unimicron, Compeq, and Flexium Interconnect , which specialized in rapid prototyping and high-volume production, leveraging advantages in cost efficiency and agile response to consumer electronics cycles.

The 2010s marked a phase of technological upgrading and diversification. With the surge in demand for high-density interconnects (HDI), flexible PCBs, and IC substrates—fueled by smartphones, IoT, and later AI and 5G—Taiwan’s turnkey services expanded into advanced areas like ultra-thin PCBs and high-speed materials. Manufacturers invested in automated processes (e.g., AOI, laser drilling) and dedicated rapid-prototyping lines to achieve feats like 24-hour delivery for samples. This era also saw increased integration with Taiwan’s semiconductor industry, enhancing capabilities in substrates and advanced packaging.

Geopolitical shifts and supply chain resilience became critical in the 2020s. As US-China tensions rose, Taiwanese PCB firms accelerated expansion into Southeast Asia (e.g., Thailand, Vietnam) to diversify production and cater to global clients’ risk mitigation needs. Despite this, Taiwan retained its core turnkey operations locally, focusing on high-value segments like AI servers, automotive electronics, and wearables. By 2025, Taiwan’s PCB industry reached an estimated $39.9 billion, with materials and equipment sectors growing robustly, underscoring its turnkey prowess.

Today, Taiwan’s Turnkey PCB Assembly services are characterized by end-to-end expertise , from design support using AI-driven DFM tools to logistics partnerships for global shipping. While challenges like cost pressures and regional competition persist, Taiwan’s synergy between semiconductor, PCBA, and electronics sectors continues to drive innovation, ensuring its status as a global turnkey leader.

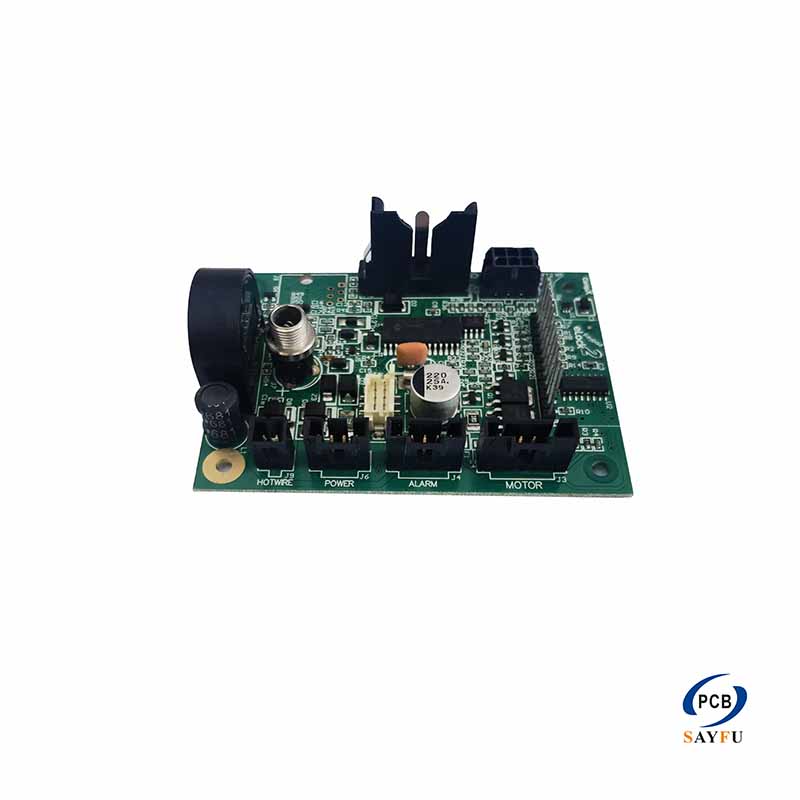

Sayfu Group’s PCBA service

Sayfu Group’s sister company Suga tech ha more than 18 SMT lines and 6 DIP lines. We can get all BOM components ready within 8-48 hours. We can provide you sales and technical support by 7/24 hours. There are more 2000 items to be finished per month. So if you have such quick turn service, please come to us.