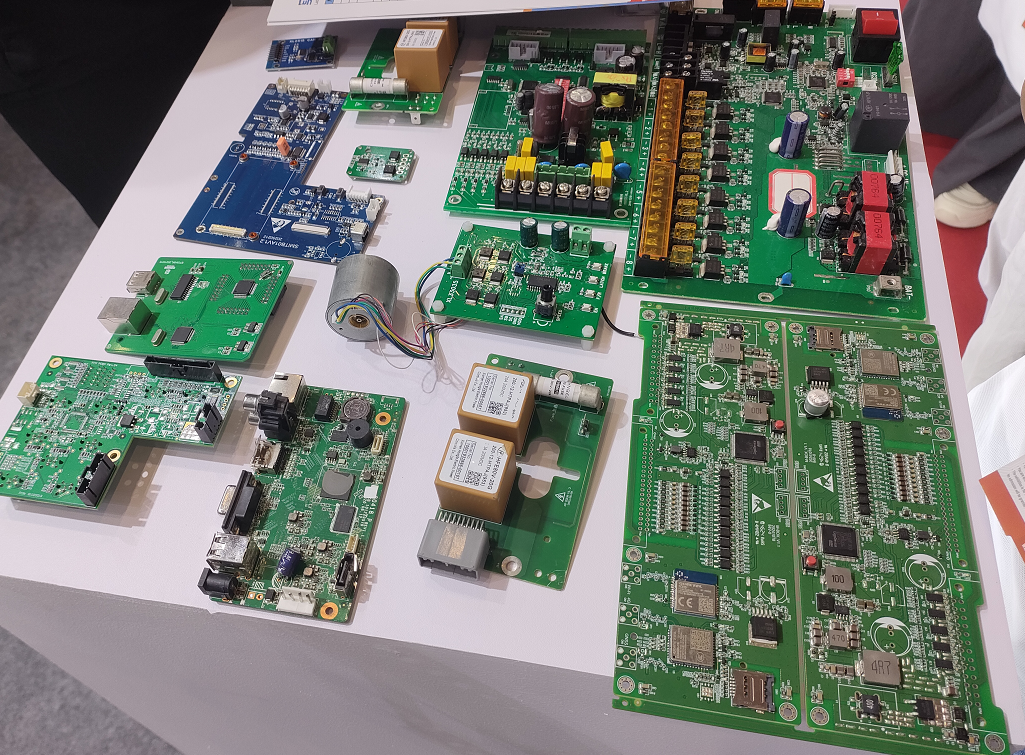

PCB board testing is the core of electronic equipment, and its proper functioning directly determines the product’s quality. Through systematic testing, its design can be verified, manufacturing defects can be discovered, and its reliability in practical applications can be ensured. A complete testing process typically involves the following key stages.

1.Visual Inspection and Basic PCB board testing

This is the first and most fundamental step in testing. Technicians carefully inspect the board for obvious physical defects, such as short or open circuits, incorrectly placed components, or poor solder joints, using a magnifying glass or microscope. Before applying power, using a multimeter to measure the resistance between the power supply and ground lines to check for shorts is a crucial safety step to prevent damage to components during subsequent tests.

2.In-Circuit Test and Flying Probe Test

In-Circuit Test (ICT) is an efficient method used during mass production. It uses a dedicated test fixture and probes connected to specific test points on the board to verify whether all components are installed correctly and whether their parameter values are within the allowed tolerance. For small batches or prototype boards, the Flying Probe test is often used. It employs movable probes for inspection. Although slower, it does not require expensive custom fixtures, offering greater flexibility.

3.Functional Test

The Functional Test for PCB is the ultimate assessment that simulates the board’s real-world operating environment. At this stage, testers provide the board with the rated operating voltage and input signals, then measure whether its output signals or overall behavior meet the design specifications. For example, testing an audio amplifier board involves inputting an audio signal and then detecting whether the output provides distortion-free amplification. Only a PCB that passes the functional test can be certified as fully functional.

In summary, combining visual inspection, in-circuit testing, and functional testing creates a rigorous system that checks the board from physical to logical aspects and from individual parts to the whole, forming the cornerstone of ensuring electronic product quality.