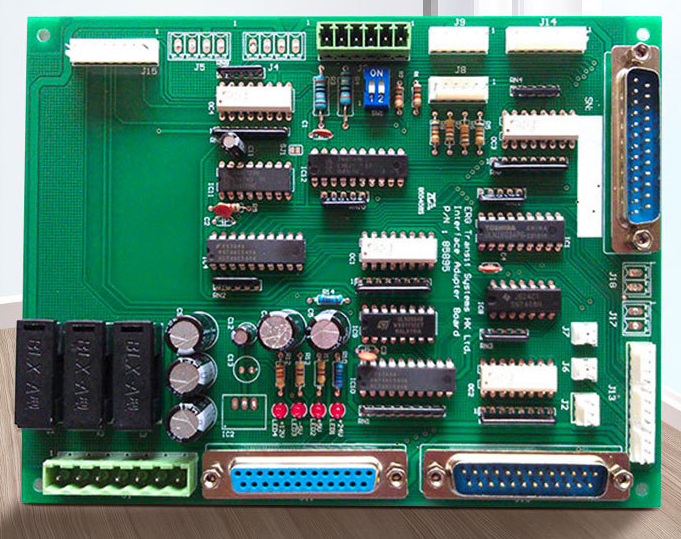

PCB assembly services are core to electronic manufacturing. Sayfu focuses on PCB assembly services, providing comprehensive solutions for these critical processes. As a support and connection carrier for electronic components, the quality and efficiency of PCB (Printed Circuit Board) — especially PCB Bare board — directly affect product performance. From PCB Bare board production to assembly services, every step matters in ensuring reliable electronic products.

One – Stop Provider of Sayfu, Full – process Escort

Sayfu offers one-stop service: from PCB design and samples to full production and part assembly. First, when customers tell us what they need, our engineers check and tweak the design to make sure it works. Then, we handle all steps in-house—making the bare board, buying parts, placing components, and more. This avoids mistakes when working with other companies.

Finally, the finished products are delivered directly after strict testing, which greatly shortens the customer’s production cycle. In addition, we also provide after – sales technical support to solve various problems in subsequent use.

Outstanding Service Advantages, Leading Competitiveness

Compared with peers, Sayfu has significant service advantages. On the one hand, we have advanced production equipment and testing instruments. Bare board circuit precision reaches ±0.02mm; assembly yield stays above 99.5%, ensuring quality.Our flexible production quickly handles small-batch, multi-variety orders, with the shortest lead time just 3 days.Meanwhile, large-scale procurement and lean management cut costs while ensuring quality, offering customers cost-effective options.

PCB assembly services:Distinctive Bare Board Features, Guaranteed Production and Assembly

Sayfu’s PCB bare boards have key features. They use high-quality FR-4 material, which handles heat well and resists corrosion. Also, surface treatments like immersion gold and spray tin make welding reliable. Additionally, multi-layer boards are laminated precisely, so signal loss is low.During production and assembly, we avoid common problems—like pads coming loose or cold solder joints. We do this by improving steel mesh design and controlling welding temperature. For complex, high-density boards, we use AOI and X-Ray checks to ensure every product meets standards.

All in all, we offer one-stop service, top-quality PCB bare boards, and reliable production skills. That’s why many electronics companies trust Sayfu for PCB bare board and assembly work. Choosing us makes your PCB buying and assembly faster and easier.