Here is a comparison between China and Germany PCB assembly industry.

Germany PCB Assembly was mature after 40 more years development while China has gained an extremely speed in recent 10 years.

Manufacturing Scale & Market Position

China is the world’s largest PCB manufacturing base, accounting for approximately 55% of global PCB production value in 2023. It dominates in large-scale electronics manufacturing, particularly for consumer electronics, telecommunications, and industrial applications. Germany, while smaller in overall scale, is a European leader in advanced PCB manufacturing with a strong focus on automotive electronics, industrial automation, and high-reliability applications.

Cost Structure & Pricing of China and Germany PCB Assembly

China offers significant cost advantages, with assembly labor rates around $3-6/hour compared to Germany’s $25-35/hour. This translates to substantial price differences:

Prototype assemblies (10 pcs): China $60-110 total vs. Germany $120-180 total

Mass production (1000+ pc): China $0.35-0.75/pc vs. Germany $1.20-2.20/pc

6-layer automotive PCB: China ~$36/unit vs. Germany ~$72/unit

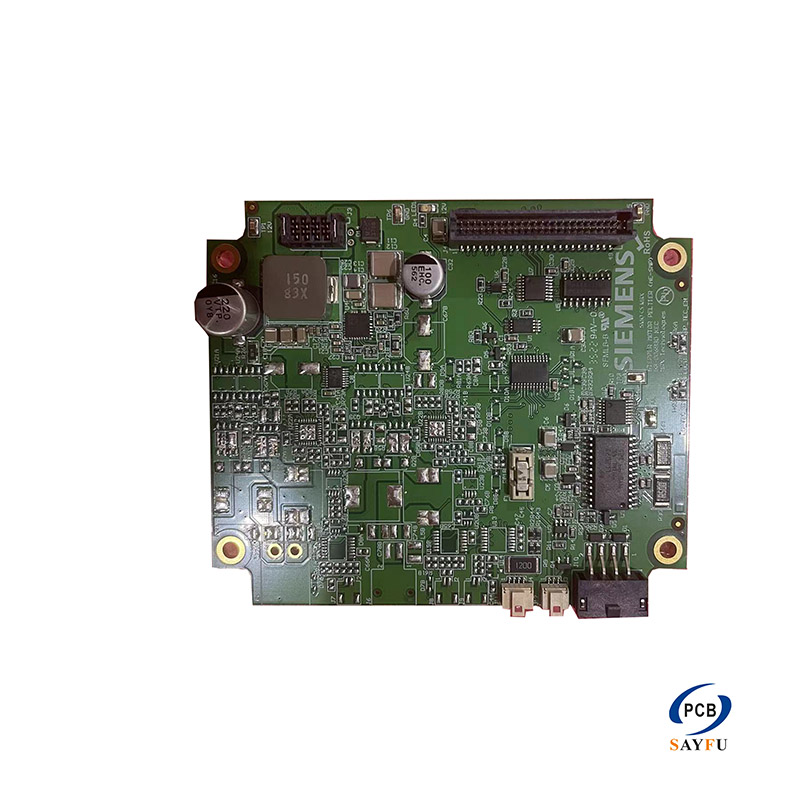

Technical Capabilities & Specialization

German PCB assembly excels in high-quality, precision manufacturing for demanding industries like automotive (35% of European PCB demand) and aerospace. German manufacturers typically emphasize strict quality control, certifications (ISO, IATF 16949), and advanced engineering support. China has developed strong technical capabilities in high-volume production and has made significant advances in high-multilayer PCBs, HDI technology, and emerging areas like AI servers and 5G infrastructure. Chinese suppliers have improved quality standards with 92% yield rates for complex orders.

Quality Standards & Certifications

Both countries have manufacturers with international certifications (ISO 9001, ISO 13485, IATF 16949). German manufacturers are particularly known for adhering to strict European quality standards and environmental regulations. Chinese manufacturers have significantly improved their quality processes, with many now implementing IPC-A-610E standards and advanced quality control systems.

Supply Chain & Logistics

China benefits from extended local supply chains and component availability in Asia, reducing material costs by 5-15% compared to importing components. However, international shipping adds $80-250 per shipment and import duties of 5-8% for European customers. Germany offers local European supply chain advantages for EU customers, with shorter lead times within Europe and no import duties for EU members.

Summary: Choosing Between China and Germany PCB Assembly

Choose China for: Cost-sensitive projects , high-volume production , established supply chains in Asia, and increasingly capable technical manufacturing .

Choose Germany for: High-reliability applications (automotive, medical, industrial), precision engineering , strict quality requirements , and local European supply chain advantages.

The choice between Chinese and German PCB assembly involves balancing cost considerations with quality requirements, technical needs, and supply chain factors . Both regions offer sophisticated manufacturing capabilities but cater to somewhat different market segments and priorities.