Multilayer PCB manufacturer are playing an increasingly crucial role in the current electronics industry, which directly reflects the growing market demand for multilayer printed circuit boards. As electronic products continue to evolve towards miniaturization and high performance, traditional double-sided PCBs have been unable to meet the complex design requirements, prompting more enterprises to seek professional Multilayer PCB manufacturer to provide more advanced solutions.

Structural differences

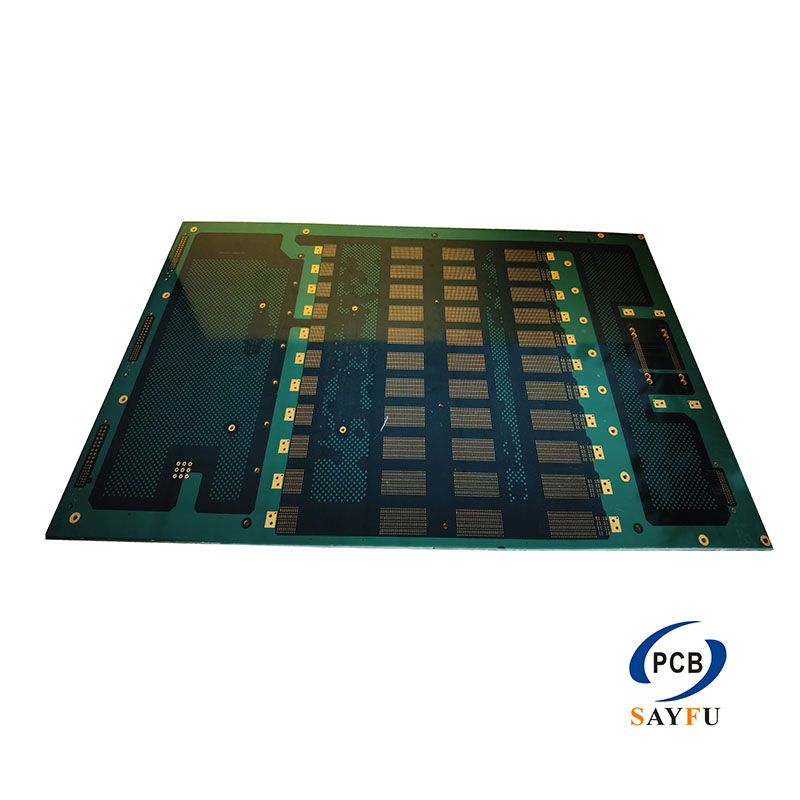

The most fundamental difference lies in the physical structure. A regular double-sided board only has two conductive layers, and they are electrically connected through holes. In contrast, a multilayer board is composed of three or more conductive layers, which are laminated together through insulating layers (prepreg) and interconnected through advanced drilling techniques such as buried hole and blind holes. This fundamental structural breakthrough enables Multilayer PCB manufacturer to achieve extremely complex and dense wiring within a limited board area. For double-sided boards, when the circuit becomes overly complex, the routing success rate will sharply decline, and even the wiring cannot be completed; while multilayer boards solve the routing success rate problem by distributing different functional circuits on different inner layers, such as dedicated power layers and ground layers. This not only resolves the routing success rate issue but also significantly reduces signal crosstalk and electromagnetic interference (EMI).

The advantages brought by the multilayer PCB manufacturer

It is precisely due to the advanced structure that multilayer boards have achieved a significant performance leap, which explains the reason for the surge in demand. Firstly, in terms of electrical performance, the independent power and ground layers provide stable voltages and low-impedance circuits, significantly enhancing signal integrity and power integrity, which is crucial for high-speed digital circuits (such as processors, FPGAs) and high-frequency analog circuits (such as 5G radio frequency modules). Secondly, multilayer boards help achieve better electromagnetic compatibility (EMC), as the inner-layer signals can be shielded by the outer-layer ground plane, reducing sensitivity to external radiation and external interference. Moreover, the multilayer structure allows for higher component density, which is a key technology for achieving product miniaturization and lightweighting. Therefore, from smartphones, laptops to data center servers, medical equipment, and automotive electronics, almost all high-performance modern electronic products rely on the professional capabilities of Multilayer PCB manufacturers.

The differences between multilayer boards and double-sided boards go far beyond the mere increase in the number of layers. It represents a comprehensive upgrade in terms of design freedom, electrical performance, and the competitiveness of the final product. This is precisely where the value of a professional multilayer PCB manufacturer lies. Through exquisite craftsmanship and technology, they empower electronic products to continuously innovate and meet the increasingly demanding market demands.