Multilayer impedance PCB is a fundamental response to the needs of modern electronic devices, which continue to become faster, smaller, and more powerful. This progression places immense pressure on the fundamental building blocks of circuitry. Signals must travel with integrity, meaning they must arrive without significant distortion or loss. Consequently, simple single-layer boards are often insufficient for high-speed applications. Therefore, designers increasingly turn to these more sophisticated solutions to meet stringent requirements.

Understanding Multilayer Impedance PCB Design

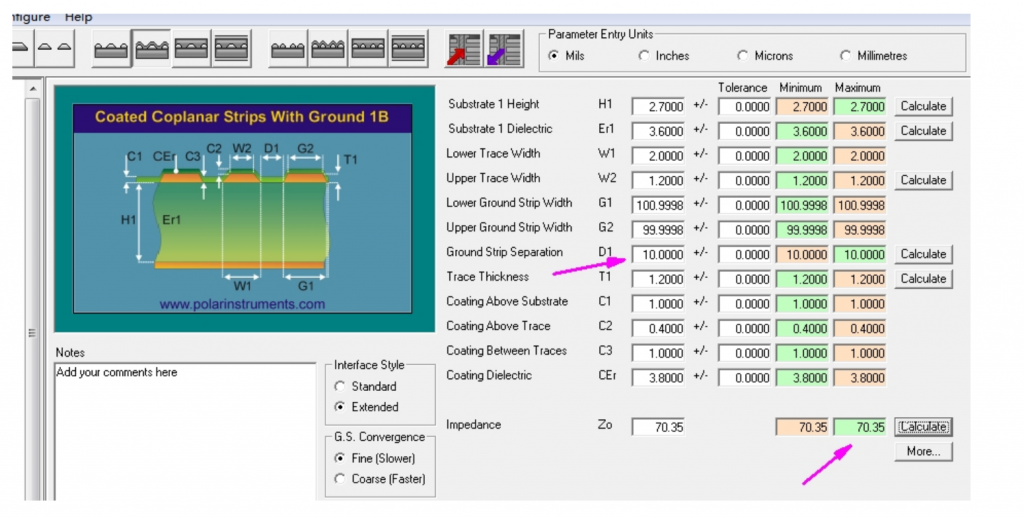

A multilayer impedance PCB is specifically engineered to control the characteristic impedance of its signal traces. This type of board consists of multiple conductive layers separated by insulating dielectric material. The impedance of a trace depends on its geometry, the dielectric constant of the surrounding material, and the distance to reference planes. Precisely controlling these factors is crucial. Furthermore, a well-designed multilayer impedance PCB ensures that signals are transmitted efficiently from the driver to the receiver.

Key Advantages and Benefits

The primary benefit of using this technology is the preservation of signal integrity. By matching the impedance throughout the transmission path, reflections and signal degradation are minimized. This leads to fewer data errors and a more reliable final product. Additionally, the multilayer stack-up allows for a dense arrangement of components and routing channels. Moreover, dedicated power and ground planes within the board provide stable voltage distribution and excellent electromagnetic shielding. As a result, the overall system performance is significantly enhanced.

The Fabrication Process of Multilayer Impedance PCB

Creating a functional multilayer impedance PCB requires a highly controlled and precise manufacturing process. It begins with careful planning of the stack-up, where the sequence of copper and dielectric layers is defined. Next, the impedance calculations are performed for critical trace widths. During fabrication, etching processes must be tightly monitored to achieve the exact trace dimensions. After that, the layers are precisely aligned and laminated together under heat and pressure. Finally, thorough testing with specialized equipment is essential to verify that the impedance values meet the specified targets.

Conclusion: A Critical Enabling Technology

In summary, the multilayer impedance PCB is not just a simple circuit carrier but a critical, high-performance component. Its ability to manage signal integrity in compact, complex designs makes it indispensable. As electronic devices continue to advance, the role of the impedance PCB will only become more prominent, enabling the next generation of technological innovation.