Mobile Phone PCBA in China,In the palm of your hand lies a marvel of modern engineering—the smartphone. At its core beats the Printed Circuit Board (PCB), and at the heart of global PCB assembly for mobile phones is China. The nation has established itself as the undisputed leader in this critical field, offering an unparalleled ecosystem that drives innovation, efficiency, and scale for brands worldwide.

1.A Complete Ecosystem for Unmatched Efficiency

China’s dominance in mobile phone PCB assembly stems from its deeply integrated supply chain. Within a single geographic region, manufacturers have immediate access to everything from raw materials like specialty substrates and copper foil to essential components such as multilayer PCBs, connectors, and chipsets. This concentration drastically reduces logistics costs and lead times, enabling incredibly fast production cycles. This “all-in-one-place” efficiency is a primary reason why global brands rely on Chinese partners to bring new models to market swiftly.

2.Advanced Technical Capabilities and High-Density Expertise for Mobile Phone PCBA

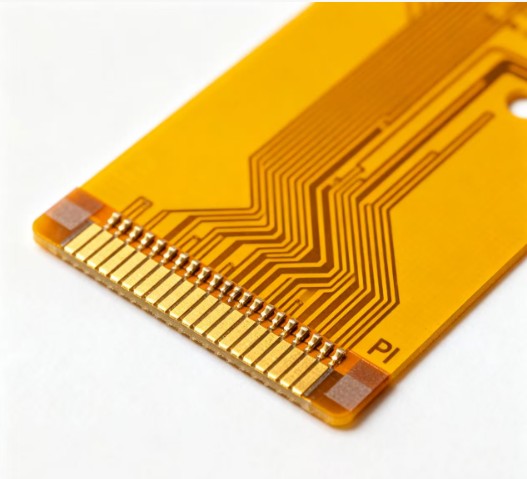

Modern smartphones demand High-Density Interconnect (HDI) and any-layer PCBs to pack immense functionality into slim form factors. Chinese assembly factories are equipped with state-of-the-art Surface Mount Technology (SMT) lines capable of placing millions of microscopic components per hour with extreme precision. Furthermore, they possess deep expertise in managing the signal integrity and thermal performance challenges associated with 5G, high-speed processing, and advanced camera systems, ensuring optimal device performance.

3.Rigorous Quality Control for Mass Production

The ability to produce at a massive scale without compromising quality is a hallmark of China’s PCB assembly sector. Factories implement rigorous quality control regimes throughout the production process, utilizing Automated Optical Inspection (AOI), X-ray inspection for hidden solder joints, and functional testing of completed board assemblies. This ensures that every PCB powering a smartphone meets high standards of reliability and performance, even when orders run into the millions of units.

The combination of scale, supply chain efficiency, and technical expertise creates a significant cost advantage. By optimizing every step of the assembly process, Chinese manufacturers make advanced mobile technology more affordable. This cost-effectiveness is a key driver in making feature-rich smartphones accessible to a global consumer base, effectively democratizing technology and connecting billions of people.

In conclusion, mobile phone PCB assembly in China is far more than a manufacturing service; it is a dynamic, innovative engine that underpins the entire global smartphone industry. Its unique blend of scale, skill, and speed continues to set the pace for mobile innovation worldwide.