IPC Standards PCB manufacturer, in today’s highly globalized electronics industry, a product might be designed in the United States, assembled in China, and ultimately sold worldwide. How can we ensure that designers, manufacturers, and quality inspectors scattered across the globe have a unified understanding of product quality? The answer lies in IPC standards. Developed by the Association Connecting Electronics Industries, these specifications have become the indispensable “universal language” and “cornerstone of quality” in electronics manufacturing, guaranteeing the reliability and consistency of everything from smartphones to aerospace equipment.

I. Industry Cornerstones:for IPC Standards PCB manufacturer

Among the numerous IPC standards, two are considered the industry “bibles.” The first is IPC-A-610, “Acceptability of Electronic Assemblies.” Using abundant color images and clear descriptions, it visually defines the “target, acceptable, and defect” conditions for processes like solder joints and component placement, making it an essential tool for production line inspectors. The other is J-STD-001, “Requirements for Soldered Electrical and Electronic Assemblies,” which focuses more on the materials, methods, and technical requirements for the soldering process itself. These two standards complement each other, jointly forming the core defense for electronic assembly quality and ensuring that both production processes and final inspections follow established rules.

II. The Precise Measure of Quality: The Product Classification System for IPC Standards PCB manufacturer

IPC standards are not “one-size-fits-all”; their essence lies in the flexible Product Classification System. The standards categorize electronic products into three classes: Class 1 applies to consumer electronics (e.g., toys), allowing a certain defect rate to control costs; Class 2 applies to industrial equipment, computers, etc., requiring higher reliability; Class 3 is used for aerospace, medical life-support systems, and other areas with extremely stringent reliability requirements, where the acceptance criteria are the most rigorous. This system allows companies to precisely apply the appropriate quality measures based on the product’s actual application scenario, achieving the optimal balance between cost and reliability.

III. Beyond Production: A Full-Process Support System for IPC Standards PCB manufacturer

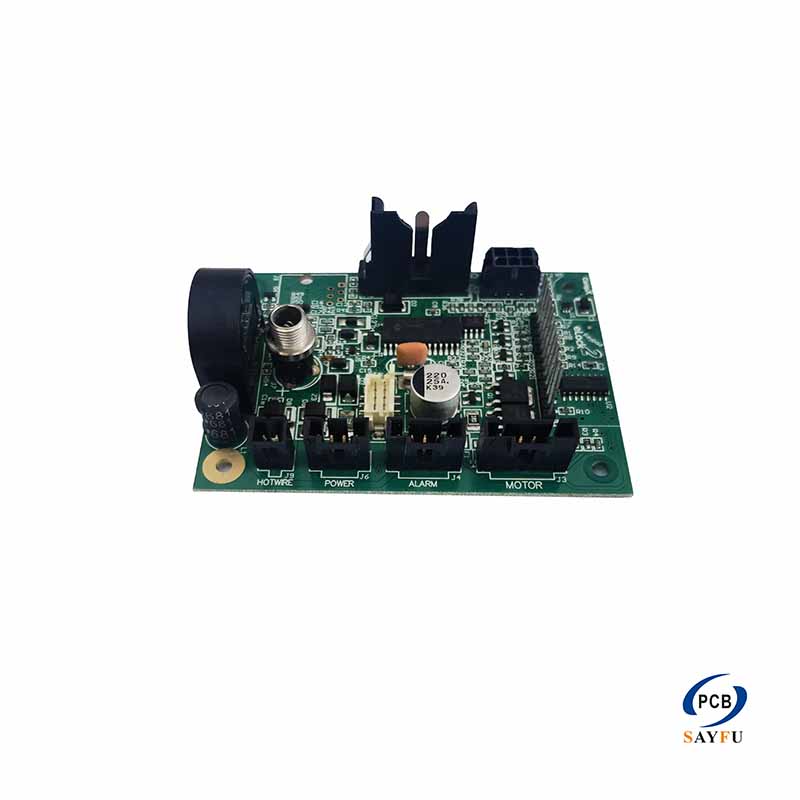

The influence of IPC standards extends far beyond the production line. On the design front, the IPC-2221 series provides general guidelines for printed circuit board (PCB) design. For PCB manufacturing, IPC-6012 specifies the qualification and performance requirements for rigid boards, while IPC-A-600 guides the acceptance of a “bare board.” Furthermore, standards like IPC/WHMA-A-620 cater to cable and wire harness assemblies. This comprehensive system of standards, covering the entire workflow from design, manufacturing, and assembly to testing and even rework, provides seamless technical support for the entire electronics supply chain, serving as a key force driving efficient industry collaboration and continuous innovation.

In summary, by defining a unified quality language and precise process requirements, IPC standards not only enhance the manufacturing capabilities of individual companies but also build a solid foundation of trust and cooperation for the global electronics manufacturing industry.