Immersion silver PCB refers to a circuit board that uses a thin layer of silver deposited on the copper traces through a chemical displacement process. This surface finish plays a critical role in protecting the underlying copper from oxidation. Moreover, it provides a highly reliable and flat surface for component assembly. As a result, it has become a popular choice for various high-frequency and demanding applications in the electronics industry.

The Process of Immersion Silver PCB Fabrication

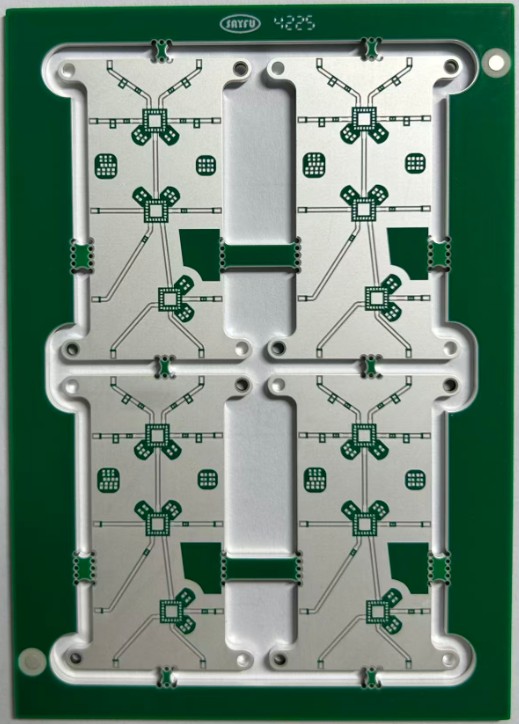

The creation of an immersion silver PCB involves a precise, multi-step cleaning and coating procedure. First, the manufactured PCB undergoes thorough cleaning and micro-etching. This step prepares the copper surface and ensures optimal adhesion. Next, the board enters the immersion silver bath. A chemical reaction occurs where silver ions deposit onto the copper, forming a thin, uniform, and pore-free layer. Finally, technicians rinse and dry the boards to complete the process, ensuring a pristine finish.

Key Advantages of an Immersion Silver PCB

Choosing an immersion silver PCB offers several significant benefits. The silver layer provides excellent surface planarity, which is crucial for fine-pitch components. It also maintains good solderability over time, ensuring strong joint formation. Furthermore, immersion silver has superior electrical performance, making it ideal for high-speed digital and RF circuits. Additionally, this finish is a lead-free and RoHS-compliant solution, meeting modern environmental standards.

Comparing Immersion Silver with Other Finishes

It is useful to compare immersion silver with other common finishes like HASL and ENIG. Unlike Hot Air Solder Leveling (HASL), immersion silver provides a much flatter surface. Compared to Electroless Nickel Immersion Gold (ENIG), it is a more cost-effective solution and avoids the potential for “black pad” failure. However, immersion silver can be susceptible to tarnishing if not stored correctly, which is a factor manufacturers must manage.

Applications and Future Outlook

The unique properties of immersion silver PCB make it suitable for many advanced applications. You frequently find it in communication infrastructure, automotive electronics, and high-performance computing devices. The industry continues to favor this finish for its balance of performance, reliability, and cost. As technology pushes toward higher signal speeds and denser boards, the demand for high-quality immersion silver print circuit board is likely to grow steadily.