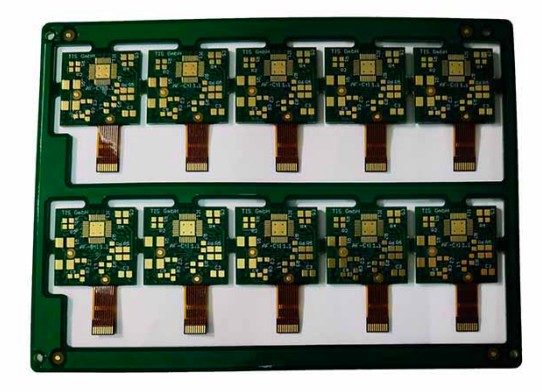

For immersion and plating gold PCB,In the manufacturing of printed circuit boards (PCB) and electronic components, surface finishes play a critical role in ensuring solderability, durability, and performance. Two commonly used gold-based finishes are immersion gold and plating gold. While both involve gold deposition, they differ significantly in process, properties, and applications.

Thickness and Uniformity for immersion gold and plating gold PCB

Immersion Gold (also known as electroless gold or ENIG) is applied through a chemical displacement reaction. The substrate (typically copper) is immersed in a gold solution, where gold ions deposit without external electrical current. This results in a thin, uniform layer.

Plating Gold (electroplating gold) uses an electrical current to reduce gold ions onto the substrate. This allows for thicker, controlled deposition and can be applied selectively with masking

Immersion gold deposits are typically thin (usually 0.05–0.2 μm) and highly uniform, even on complex geometries.

Plating gold can achieve greater thickness (ranging from 0.5 to several microns), but uniformity may vary on irregular surfaces without proper current distribution.

Performance and Applications for immersion gold and plating gold PCB

Immersion gold offers excellent flatness, oxidation resistance, and is ideal for fine-pitch components and wire bonding. It is widely used in high-reliability PCBs and modern electronics.

Plating gold provides superior wear resistance, thicker protection, and better electrical conductivity. It is preferred for connectors, switches, and components subject to frequent friction or high current.

Cost and Durability

Immersion gold is generally more cost-effective for thin layers and simplifies the process by eliminating electrical equipment. However, it may be less durable in high-wear scenarios.

Plating gold, though often more expensive due to gold consumption and energy use, offers longer-lasting performance in demanding environments.

In summary, choose immersion gold for precision and cost efficiency in solderable finishes, and opt for plating gold when durability and thick gold layers are critical.