High-frequency 6G PCB materials in application scenarios such as 5G communication, millimeter wave radar, and satellite communication, printed circuit boards serve as the “skeleton” of electronic components, and their material properties directly determine the stability and reliability of signal transmission.

High frequency PCB materials are becoming the core materials in the field of high-speed signal transmission due to their low dielectric constant (Dk), low loss factor (Df), and other characteristics.

Core characteristics of high-frequency 6G PCB materials

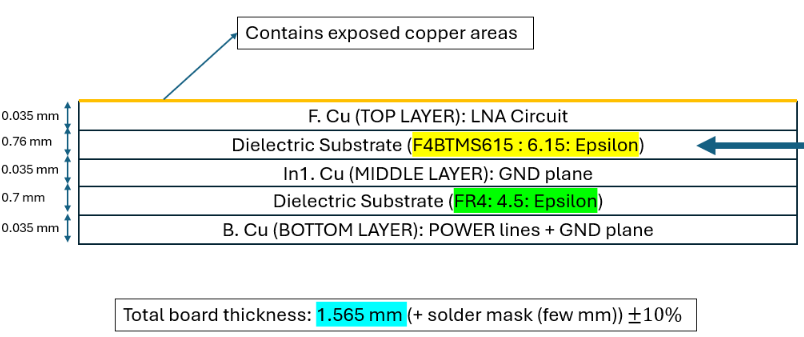

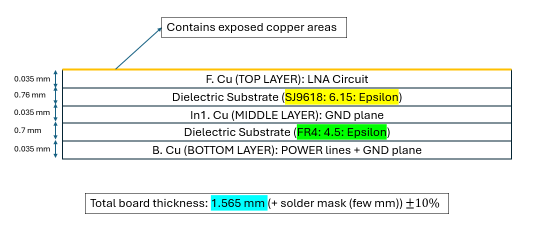

High frequency PCB materials typically use special substrates such as polytetrafluoroethylene (PTFE) and thermosetting resins, with dielectric constants as low as 2.2-3.5 and loss factors below 0.001.

This characteristic significantly reduces the attenuation of signals during transmission, for example, in the 28GHz frequency band, the loss of traditional FR4 materials is more than 10 times that of high-frequency materials.

In addition, high-frequency materials also have excellent heat resistance (Tg value>280 ℃) and dimensional stability, which can adapt to the working environment of high-power devices.

Key application scenarios

1.5G base station: The high-frequency PCB is the core component of AAU (active antenna unit) and needs to support signal transmission in the millimeter wave frequency band (24-100GHz). A test of a certain base station showed that using Rogers RO4350B material for PCB reduces insertion loss by 40% compared to FR4 material in the 28GHz frequency band, resulting in a 15% increase in base station coverage

2.Satellite communication: Low orbit satellite constellations require higher requirements for PCB lightweighting and high-frequency performance. A certain satellite project uses polyimide based high-frequency materials to reduce the weight of the single board by 30% while maintaining signal integrity.

3.Automotive radar: 77GHz millimeter wave radar requires high-frequency PCB to achieve high-precision ranging. A test conducted by a certain car company shows that the radar module using Rogers RT5880 material maintains a distance measurement error within ± 0.5 meters in an environment ranging from -40 ℃ to 125 ℃.

Technical Challenges and Development Trends

High frequency PCB manufacturing faces three major challenges: material costs are 3-5 times higher than FR4; The drilling accuracy should reach ± 0.05mm; the interlayer alignment accuracy should be ± 25 μ m. At present, the industry is breaking through through through the following paths:

- Material innovation: Develop modified polytetrafluoroethylene (PTFE) composite materials to expand the adjustable range of Dk value to 2.2-4.5.

- Process optimization: Using laser drilling technology, the roughness of the hole wall is controlled within 10 μ m to reduce signal reflection.

- Integrated design: By using embedded component technology, passive components are integrated into the PCB to reduce parasitic effects

According to Prismark’s prediction, the global high-frequency PCB market size will reach 6.8 billion US dollars by 2025, with a compound annual growth rate of 12.3%.

With the advancement of 6G technology research and development and low orbit satellite networking, high-frequency PCB materials will play a more critical role in fields such as communication, aerospace, and national defense.

Chinese enterprises such as Shengyi Technology and Huazheng New Materials have broken through the mass production technology of high-frequency materials and are gradually breaking international monopolies, providing new impetus for the development of the global high-frequency electronics industry.