Heavy Copper PCBs are critical components in wind turbine inverters, playing a pivotal role in ensuring stable power conversion and operation in renewable energy systems. As the global shift toward clean energy accelerates, the demand for high-performance PCBs capable of handling large currents and extreme environmental conditions has surged.

Shenzhen’s Technological Prowess in Heavy Copper PCB Manufacturing

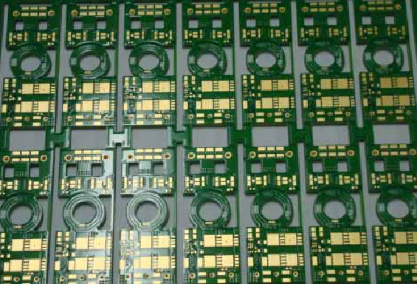

Shenzhen leads China’s electronics innovation and shines in this field. It has a full PCB supply chain. Local firms have mastered key tech like heavy copper plating and high-precision etching. This lets them mass-produce PCBs with 10-20oz thick copper layers—thick enough to handle big electrical loads, up to 200-500A, which inverters need.

What’s more, Shenzhen’s unique stepped lamination process is a game-changer. It keeps these heavy copper PCBs stable even in tough outdoor spots. Whether it’s -40℃ in cold regions or 125℃ in hot areas, the PCBs work smoothly. This reliability is key for wind turbines, which sit exposed to harsh weather year-round.

Sayfu: Delivering Comprehensive Solutions from Design to Mass Production

Based in Shenzhen, Sayfu specializes in PCB manufacturing. Specifically, the company covers small-to-medium batch, quick-turnaround single and double-sided boards. As well as mass-produced high-layer count through-hole boards and heavy copper boards.

Furthermore, as a professional high-tech manufacturer, Sayfu produces complex rigid PCBs with 1-24 layers. Importantly, our company is certified by ISO9001, UL (E511658), ISO14001, and TS16949. Consequently, Sayfu focuses on delivering quality, cost-effectiveness, service, and sustainable development.Offering end-to-end services from design to mass production.

To achieve this, our company employs rigorous processes. During the design phase, 3D simulation optimizes current paths. Additionally, during production, automated inspection systems, tightly control heavy copper PCB copper thickness tolerance within ±5%.

Therefore, Sayfu ensures consistent performance. As a result, its products serve numerous international wind power projects. Ultimately, they help boost inverter power density by 30%, delivering reliable “Chinese solutions” to the global wind energy industry.