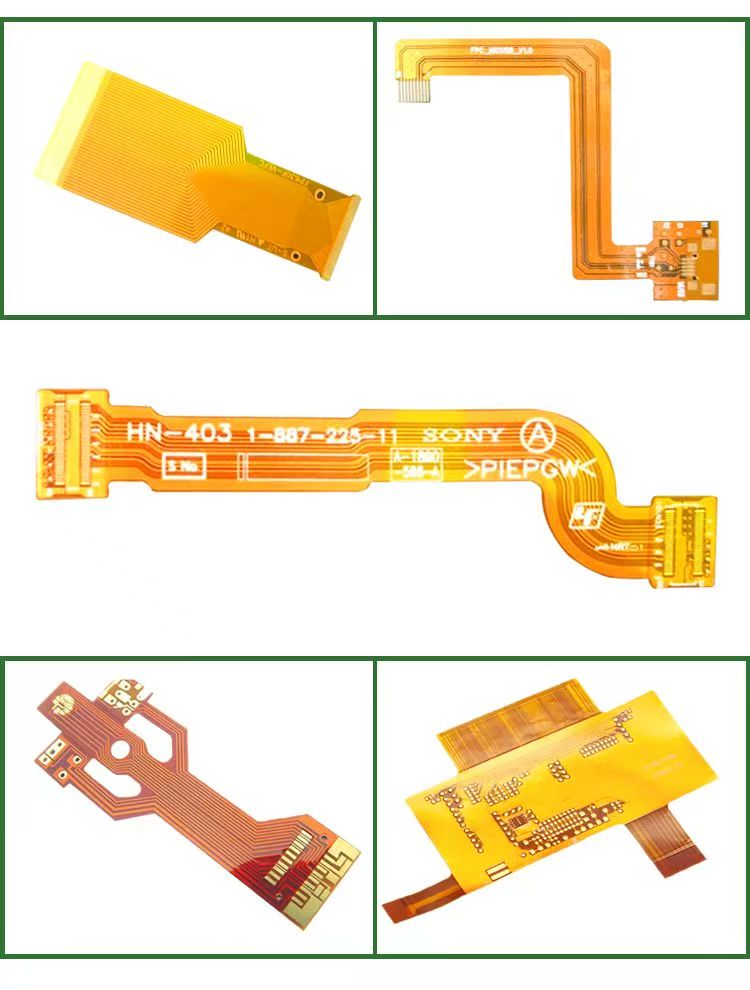

FPC board refers to single-layer, double-layer, and multi-layer flexible copper foil substrates using polyimide (PI) or polyester (PET) as the base material, including adhesive and non-adhesive types. The purpose of FPC board testing is to establish unified standards for the appearance and quality of FPC boards. These standards serve as the basis for evaluating flexible circuit products, helping to optimize manufacturing processes, reduce resource waste and environmental pollution caused by unnecessary scrapping.

Test Methods for FPC board

- Primary inspection methods and tools include visual inspection, magnifying glasses, and rulers.

- Other applicable test instruments or equipment can be adopted when necessary to ensure inspection comprehensiveness.

Basic Testing Standards for FPC board

- Appearance of the substrate film surface and covering layer.

- Deviation between the connecting plate and the covering layer.

- Seepage of adhesive and cover coating.

- Conductor discoloration under the covering layer: After a 96-hour humidity resistance test at 40°C and 90% humidity, the product must still meet voltage resistance, bending resistance, flexural durability, and welding resistance requirements.

- Missing coating of the covering layer and poor electroplating adhesion.

Precautions

- The conductor part of FPC requires surface plating (anti-rust treatment), such as nickel plating, gold plating, OSP, or tin plating.

- The storage environment should be free of corrosive gases, with temperature controlled at 20±5°C and relative humidity (RH) within 70%.

- Under the above storage conditions, the product has a valid shelf life of 6 months from the date of delivery.

- FPC boards are widely used in consumer electronics, automotive electronics, and aerospace fields, so strict testing ensures stable performance in complex operating environments.

Summary

FPC board testing is a core link to ensure product reliability and application adaptability. By adhering to unified testing standards, adopting scientific inspection methods, and complying with storage and anti-rust requirements, it not only guarantees the appearance and performance of FPC boards but also promotes the standardized development of the industry, laying a solid foundation for the stable operation of terminal products in various fields.