Flex PCBS demand is growing very fast, according to the data in 2018, the global PCB output value reached 63.5 billion us dollars, and the FPC output value rose to 12.7 billion us dollars, becoming a relatively fast growing project in the PCB industry, and China’s FPC market accounts for about half of the world.

Currently, the size of FPC market in China has grown to 31.6 billion yuan. It is estimated that by 2021, China’s FPC market has the opportunity to reach 51.6 billion yuan, with a compound annual growth rate of 10%.

Now, the usage of Flex PCBS of mainstream Chinese brands ranges from 10 to 15 tablets, while the usage of iPhone X is as high as 20 to 22 tablets. It can be seen that there is still a lot of room for the use of Chinese smartphones in FPC. Meanwhile, the value of FPC per unit has reached $10.

Applications of Flex PCBS in Electronic Products

Flexible Printed Circuit Boards (Flex PCBs) have become indispensable components in modern electronic products, offering unique advantages like flexibility, lightweight design, and space efficiency. Their ability to bend and conform to complex shapes makes them ideal for compact and wearable devices. In the consumer electronics sector, Flex PCBs are widely used in smartwatches, fitness trackers, and foldable smartphones, enabling sleek designs and comfortable user experiences.

The automotive industry leverages Flex PCBs in advanced driver-assistance systems (ADAS) and in-vehicle infotainment, where their durability and vibration resistance enhance reliability. Emerging applications include humanoid robots, where FPC contribute to servo motors, sensors, and battery management systems. Medical devices, such as portable monitors and implantable instruments, benefit from their biocompatibility and miniaturization capabilities.

Additionally, Flex PCBs play a crucial role in communication technologies, with applications in antennas and wireless modules,. It can support multiple frequency bands for Wi-Fi and GNSS5. The integration of rigid-flex PCBs further expands their use in high-performance electronics, combining the durability of rigid boards with the adaptability of flexible circuits. As technology advances, FPC continue to drive innovation across industries, enabling more compact, efficient, and versatile electronic products.

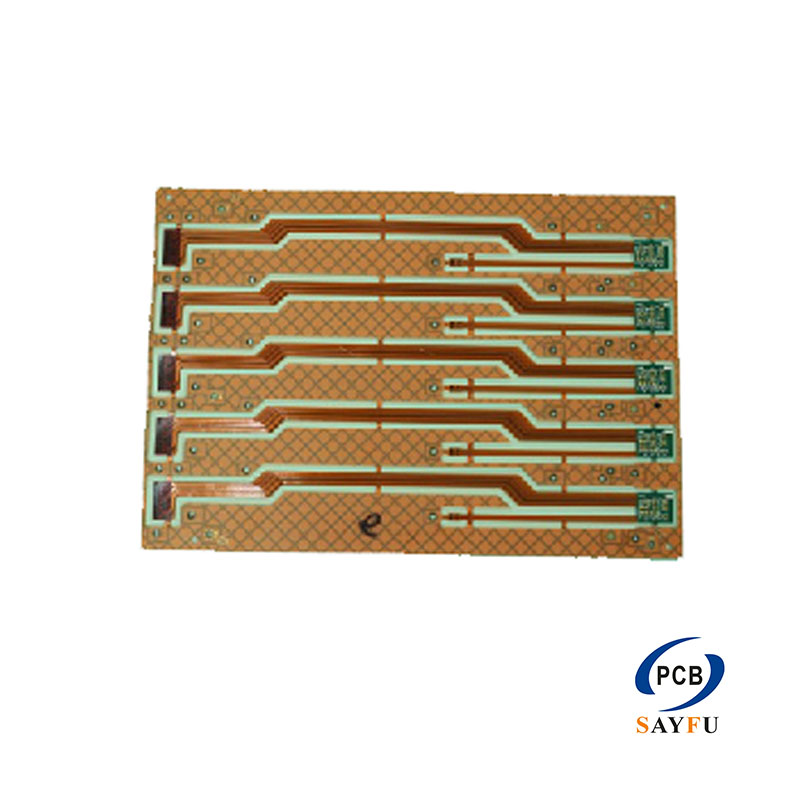

Sayfu also has a very mature technology for make Flex Board, in many years of special technical research has gradually cultivated a skilled, overall strength in the industry’s highest level of high-speed team.