What is EMS PCB?

EMS PCB refers to a specialized service provided by Electronics Manufacturing Service providers:

- Design and Prototyping: Ideas into functional PCB designs.

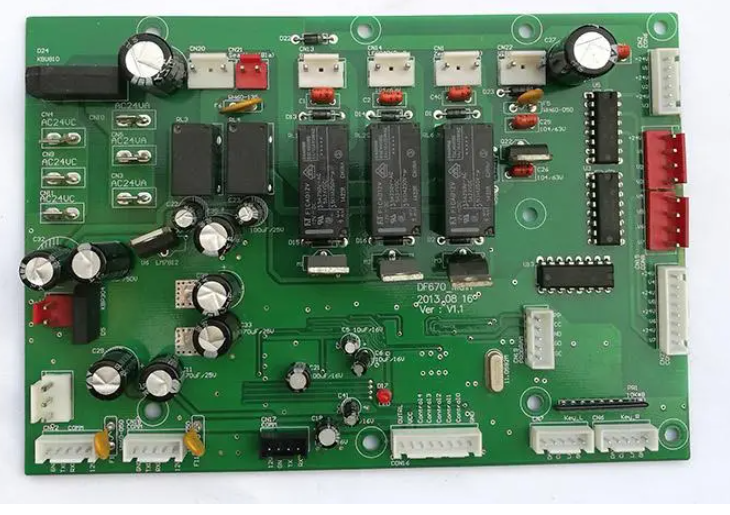

- PCB Assembly: Using SMT advanced technologies .

- Testing and Quality Assurance: Ensuring that the PCBs meet performance and safety standards.

- Logistics and Delivery: Managing the supply chain to deliver finished PCBs on time.

EMS providers cater to a wide range of industries, Such as consumer electronics, automotive, medical devices, and telecommunications.

Electronics Manufacturing Services is very importance

EMS PCB services play a vital role in enabling businesses to stay competitive. Here’s why:

1. End-to-End Manufacturing Solutions

EMS providers offer comprehensive services , from Layout to final delivery. Therefore can reduce businesses to manage multiple suppliers, streamlining operations and reducing complexity.

2. Cost Efficiency

By outsourcing PCB manufacturing to EMS providers, companies can save on capital investment in expensive equipment, labor, and infrastructure. So this makes EMS PCB Assembly for Electronics particularly appealing to startups and small businesses.

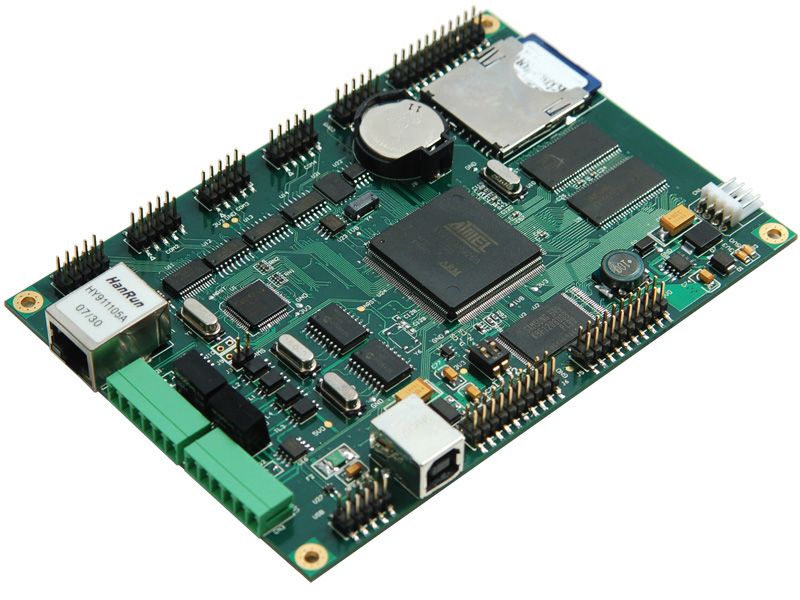

3. Access to Advanced Technology

EMS providers utilize cutting-edge equipment and techniques, such as SMT, BGA, and HDI . These technologies enable them to produce high-quality,Moreover complex PCBs that meet modern design requirements.

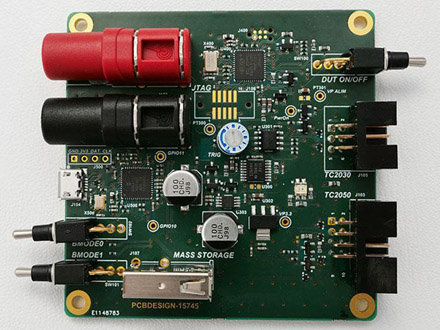

4. Quality and Reliability

EMS providers adhere to strict quality control standards. in the mean time from functional testing to thermal In addition mechanical stress tests,Importantly to ensure that each board meets industry and customer requirements.

Key Industries Using Electronics Manufacturing Services

EMS PCB services are utilized across a diverse range of industries. such as below:

- Consumer Electronics: Smartphones, smart home devices.

- Automotive: ADAS, infotainment systems, Moreover electric vehicle components.

- Medical Devices: Diagnostic equipment, monitoring devices, In addition imaging systems.

- Telecommunications: Routers, switches, and 5G infrastructure equipment.

- Industrial Equipment: Automation systems, control panels,Additionally power management systems.

The EMS PCB Process

The EMS PCB production process involves several key stages:

1. Design and Prototyping

Customer provide initial design files, such as Gerber files, or collaborate with EMS providers to create optimized designs.

Prototypes are then developed for testing and validation.

2. Component Sourcing

EMS providers procure components from trusted suppliers,Because of this to ensuring quality standards.

3. PCB Assembly

Using techniques like SMT and THT, Whereas can providers assemble the components onto the PCB.

4. Testing and Quality Control

Each assembled PCB undergoes rigorous testing, So including functional testing, X-ray inspection, and thermal to ensure reliability.

5. Logistics and Delivery

The final PCBs are packaged securely and delivered to the client, Moreover ready for integration into the end product.

Why Choose Sayfu Multilayer Circuits Co., Ltd ?

we specialize in providing top-notch EMS PCB solutions tailored . In addition ith years of experience and a dedicated team, we are committed to delivering excellence in every project. For instance:

- State-of-the-Art Facilities: PCB designs.

- Customizable Solutions: we offer flexible services to match your needs.

- Global Expertise: Serving clients across various industries and regions.

- Quality Assurance: Strict adherence to international quality standards, In addition including ISO certifications.

- On-Time Delivery: Efficient production schedules to meet tight deadlines.