Dupont Material is a high frequency material that can be used in telecom and military.

SAYFU is a professional manufacturer of high-precision, high-density, and high-reliability rigid-flex PCB, whose material can be Dupont brand. It has more than ten years of production and manufacturing experience. Our company exports the bare PCBs to North America and Israel.

The company’s products involve single-sided and multi-layer PWB, 2 to 10 layers of Rigid-flex boards are widely used in high-tech fields such as computers, digital products,instrumentation, industrial equipment, communications and medical care, automobiles, etc. There are good special purchases and reserve resources. DuPont materials and Panasonic materials are widely and stably used, we have enough stock for each specification. For normal factory, the materials purchasing time is around 15days, while there is no need for Sayfu.

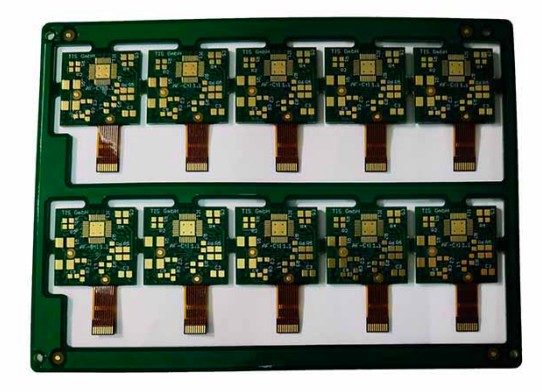

Below example features a 6L rigid-flex PCB using Dupont materials. There are 6L in rigid area while 3 layers in flexible part. This PCB serves in Huawei’s telecom 5G base stations.

The Main Difficulties of Making Rigid-flex PCB using Dupont Material

Material Compatibility & Dimensional Stability for Dupont Material

DuPont polyimide films (like Pyralux® or Kapton®) exhibit different thermal expansion coefficients (CTE) compared to rigid sections (typically FR-4). This mismatch during thermal cycling (laminating, soldering) causes warping, delamination, and stress fractures at rigid-flex interfaces.

Adhesive Processing Complexity for Dupont Material

The adhesives bonding polyimide layers to copper foils require highly controlled lamination parameters (temperature, pressure, time). Achieving void-free bonds without resin starvation or excessive flow is difficult, impacting reliability and signal integrity.

Precision Multilayer Registration

Aligning multiple thin, flexible layers with rigid sections demands extreme precision. Handling delicate polyimide films during drilling, plating, and imaging processes increases the risk of misalignment, wrinkles, and tears, reducing yield.

High-Temperature and Chemical Sensitivity

Processing steps like solder reflow expose circuits to high stresses. Polyimide films, while generally thermally stable, remain sensitive to excessive thermal shock and harsh chemicals used in etching or cleaning, potentially degrading performance or lifespan.

Reliability & Yield Trade-offs

Integrating dissimilar materials inherently introduces failure points (e.g., flex-to-rigid transitions). Ensuring long-term reliability under mechanical flexing necessitates sophisticated design and stringent process control, often leading to lower manufacturing yields and higher costs compared to standard rigid PCBs.

These challenges highlight the demanding nature of utilizing DuPont material for high-performance rigid-flex PCBs, requiring specialized expertise and process optimization.