The core difference between Ceramic PCB and FR4 PCB

Ceramic PCB, as a high-performance circuit board, has a comprehensive gap compared to conventional FR4 PCB. Ceramic PCB uses ceramic materials such as alumina and aluminum nitride as the substrate. Its most significant advantage lies in its extremely high thermal conductivity (up to several tens to hundreds of times that of FR4), excellent thermal stability, and matching thermal expansion coefficient (CTE) with semiconductor chips. This means it can efficiently dissipate the heat generated by high-power components, preventing the system from failing due to overheating, and ensuring the reliability of connections under drastic temperature changes. The FR4 PCB is composed of glass fiber and epoxy resin. It has extremely poor thermal conductivity and limited high-temperature resistance. It is prone to deformation and decomposition when exposed to high temperatures.

The main reason for the scarcity of market applications:

Despite its excellent performance, Ceramic PCB has an extremely low market share in the overall PCB market. The primary bottleneck lies in its extremely high manufacturing cost. The raw materials for ceramic substrates are expensive, and their processing technology is complex, requiring special techniques such as laser drilling, high-temperature co-firing, or thick film printing. The equipment investment and process difficulty are much higher than the mechanical drilling, chemical etching, and lamination processes of FR4, resulting in a significant increase in production costs. Secondly, the limitations of its physical properties also restrict its application scope. Ceramic materials are inherently brittle and difficult to manufacture on a large scale, and have weak resistance to mechanical impact, which are fatal drawbacks in applications requiring flexibility or large panels.

Conclusion: The trade-off between performance and cost

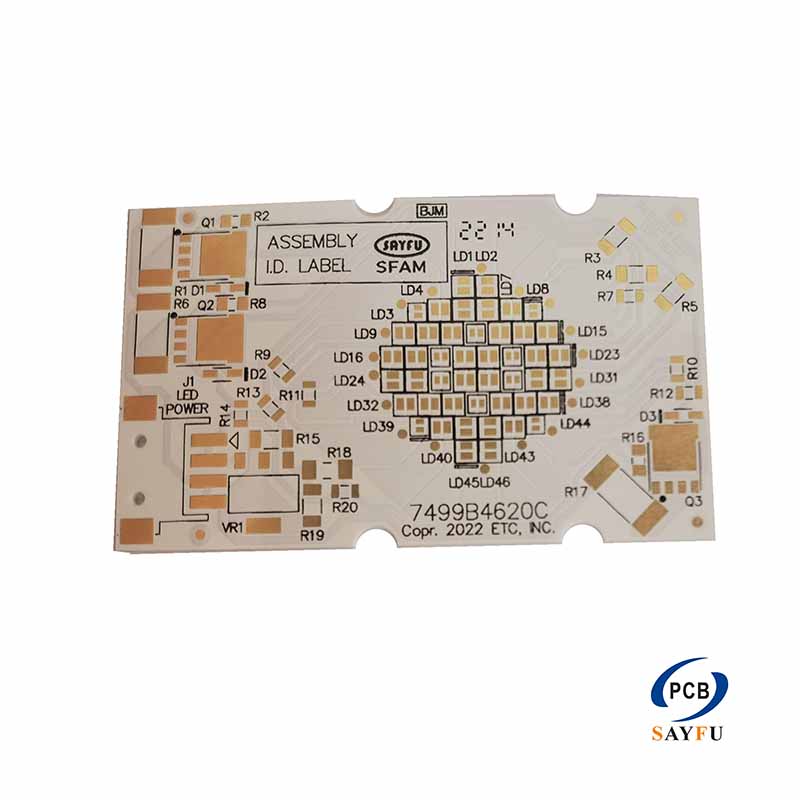

In summary, the difference between Ceramic PCB and FR4 PCB lies in the gap between “top performance” and “economical and practical“. The reason for its limited market application is not due to poor technology, but rather the extremely high cost-effectiveness threshold. Therefore, its application is strictly limited to those fields where cost is not a concern and where there are extreme requirements for performance and reliability, such as aerospace, high-power LED lighting, LiDAR, microwave radio frequency modules, etc. It cannot become the absolute mainstream of the electronics industry like the universal and inexpensive FR4 PCB.