Bluetooth Rigid-Flex PCB have evolved into compact, high-performance, and ergonomic wearable devices. A key technological driver behind this evolution is the widespread adoption of Rigid-Flex Printed Circuit Boards (PCBs), which offer unique advantages in design flexibility, space efficiency, and reliability.

What is Rigid-Flex PCB?

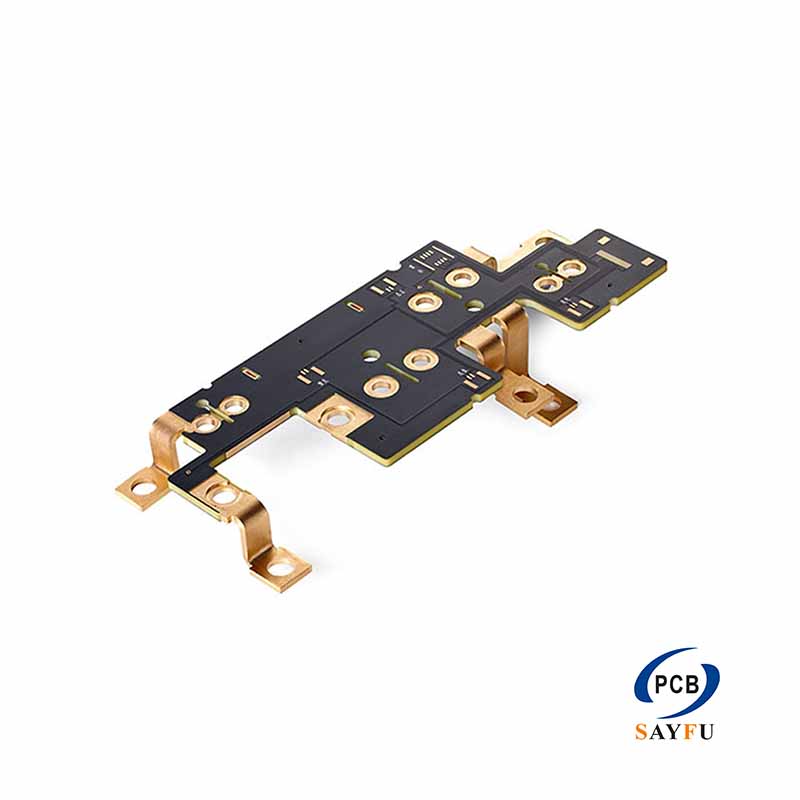

Rigid-Flex PCBs combine rigid and flexible substrates into a single integrated unit. The rigid sections provide structural support for mounting components, while the flexible segments enable bending and folding to fit compact and irregular shapes.

Why Rigid-Flex is Ideal for Bluetooth Headsets

- Space Optimization

Bluetooth headsets require extreme miniaturization. Rigid-Flex boards allow efficient 3D packaging by bending around components such as batteries, speakers, and microphones, maximizing space utilization without sacrificing functionality. - Enhanced Durability

Unlike traditional rigid PCBs, Rigid-Flex designs reduce the need for connectors and interconnects, which are common points of failure. The seamless integration of rigid and flexible sections improves resistance to vibration, mechanical stress, and repeated movement—critical for wearable devices. - Improved Signal Integrity

High-speed audio data transmission in Bluetooth headsets demands minimal signal loss and interference. Rigid-Flex PCBs enable shorter and more direct signal paths between components (e.g., Bluetooth chips, audio codecs, and antennas), reducing electromagnetic interference (EMI) and ensuring stable performance. - Lightweight and Ergonomic Design

The lightweight nature of flexible circuits contributes to overall product comfort. By eliminating bulky connectors and rigid structures, manufacturers can create sleek, form-fitting designs that enhance user experience. - Streamlined Assembly

Rigid-Flex boards integrate multiple circuit layers and functions into a single unit, simplifying the assembly process and reducing labor costs. This integration also enhances production consistency and scalability.

Applications in Bluetooth Headsets

- Microphone and Audio Processing: Flexible sections connect microphones and speakers to main rigid boards, ensuring precise alignment and acoustic performance.

- Battery Management: Rigid-Flex PCBs bend around batteries, optimizing space while maintaining stable power delivery.

- Antenna Integration: Flexible substrates allow antennas to be placed optimally for signal reception, avoiding metal obstructions.

Challenges and Considerations

While Rigid-Flex PCBs offer significant benefits, their design and manufacturing require specialized expertise. Careful planning of bend radii, material selection (e.g., polyimide films), and controlled impedance are essential to avoid mechanical fatigue and signal degradation.

Conclusion

Rigid-Flex PCB technology has become a cornerstone of modern Bluetooth headset design, enabling smaller, lighter, and more reliable products. As wearable technology continues to advance, Rigid-Flex solutions will play an increasingly vital role in pushing the boundaries of innovation. For brands seeking competitive edge, partnering with experienced Rigid-Flex manufacturers is crucial to leveraging these advantages effectively.