The Automotive Electronic PCB is the fundamental building block of modern automotive electronics. As vehicles evolve from purely mechanical machines into sophisticated electronic platforms, the demand for advanced PCBs is experiencing unprecedented growth. This surge is driven by a convergence of major technological shifts within the automotive industry, pushing PCB manufacturers to innovate rapidly to meet new requirements for complexity, reliability, and performance.

Key Drivers of Market Expansion for Automotive Electronics PCB

Several pivotal trends are fueling the growth in automotive PCB applications. The most significant is the rapid advancement towards electric vehicles (EVs). EVs rely heavily on PCBs for critical systems absent in traditional cars, including battery management systems (BMS), power inverters, and onboard charging modules. Secondly, the push for advanced driver-assistance systems (ADAS), such as adaptive cruise control and automatic emergency braking, requires a suite of sensors (radar, LiDAR, cameras) each dependent on high-frequency, reliable PCBs. Furthermore, the trend towards vehicle connectivity (V2X) and enhanced infotainment systems creates substantial demand for consumer-grade and high-speed PCBs within the cabin.

Evolving PCB Technology and Materials for Automotive Electronic PCB

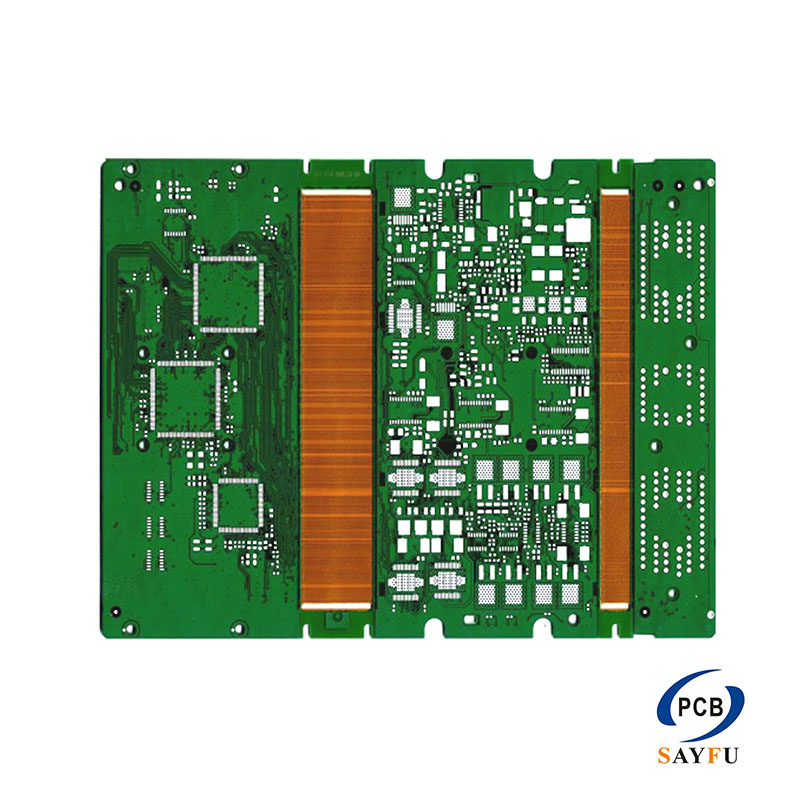

To meet the stringent demands of automotive applications, PCB technology is advancing significantly. There is a major shift from standard FR-4 substrates to more sophisticated materials like high-temperature laminates and ceramic-filled PTFE composites for high-frequency radar applications. The complexity of boards is also increasing, with a growing adoption of High-Density Interconnect (HDI) designs and multi-layer boards to accommodate more components in a smaller space. Crucially, automotive PCBs must demonstrate exceptional reliability and longevity, capable of withstanding extreme temperatures, vibrations, and humidity over the vehicle’s entire lifespan, which far exceeds that of consumer electronics.

Future Outlook and Challenges

The growth trajectory for automotive electronics PCBs is expected to remain strong for the foreseeable future. The industry’s ultimate goal of widespread autonomous driving will necessitate an even greater sensor and computing payload, further increasing PCB content per vehicle. However, this growth is not without challenges. The automotive supply chain demands rigorous quality standards, such as IATF 16949, and any component failure can have serious safety implications. Additionally, navigating global semiconductor shortages and managing the increasing cost and complexity of PCB design and manufacturing will be critical hurdles for the industry to overcome. In conclusion, the PCB market is firmly in the fast lane, driven by the unstoppable electrification and digitalization of the automobile.