From Consumer Electronics to Aerospace circuit board, As the “skeleton” and “nerves” of modern electronic equipment, the technological level of Printed Circuit Boards (PCB) directly determines the performance and boundaries of electronic products. From the compact world in our palms to spacecraft exploring the vast universe, innovative applications of PCB are driving profound transformations across various industries.

1.Consumer Electronics: Moving Towards Extreme Thinness, High Frequency, and High Speed for Aerospace circuit board

In the fields of smartphones, tablets, and wearable devices, PCB technology pursues maximum functional integration within limited space. High-Density Interconnect (HDI) boards and any-layer HDI technologies have become mainstream, enabling thinner phones and stronger performance. Simultaneously, to accommodate high-speed communication standards like 5G and Wi-Fi 6E, extremely high demands are placed on the signal integrity, thermal dissipation, and low-loss characteristics of PCB materials, driving the widespread application of new materials such as Modified Polyimide (MPI) and Liquid Crystal Polymer (LCP).

2. Automotive Electronics: Supporting the Intelligent and Electrified Revolution

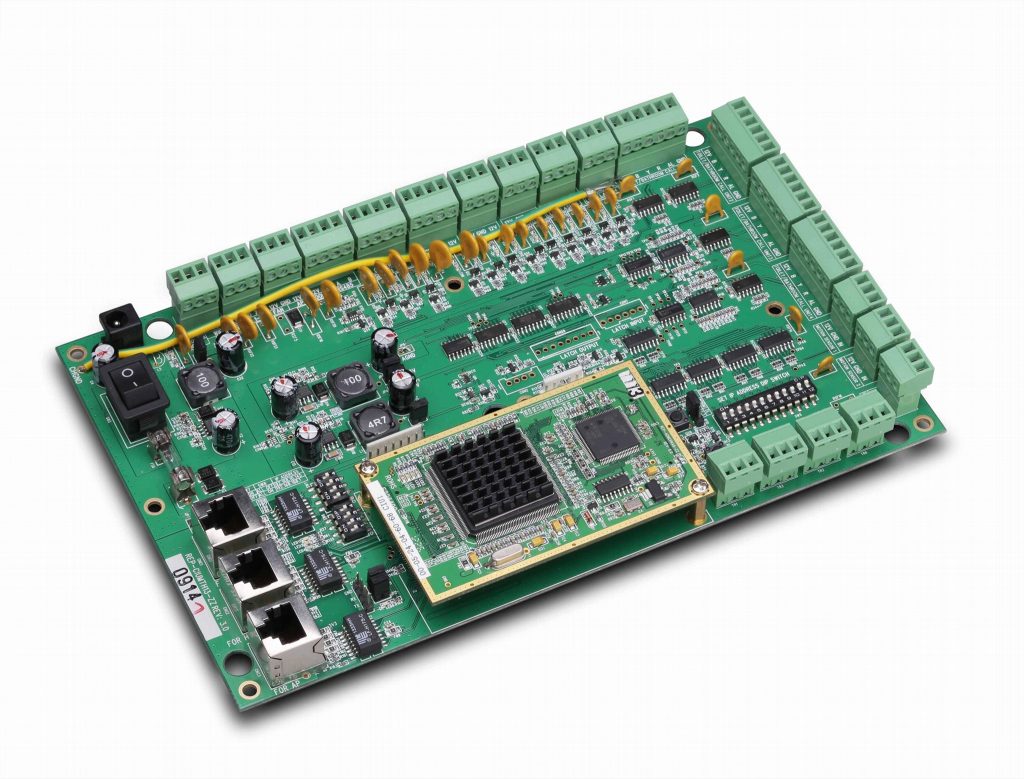

As vehicles advance towards the “new four modernizations” (typically electrification, connectivity, intelligence, and sharing), the demand and technical complexity for PCBs are surging. In powertrain systems, highly reliable PCBs capable of handling high currents are crucial for Battery Management Systems (BMS) and motor controllers. In the realm of autonomous driving, components like automotive radar, high-definition cameras, and Advanced Driver-Assistance Systems (ADAS) control units all rely on high-frequency, high-speed PCBs to ensure the accuracy and real-time performance of data processing. Their reliability is directly related to driving safety

3. Medical Devices: High-Precision and High-Reliability Life Guardians for Aerospace circuit board

In the medical field, the reliability of PCBs is a matter of life and death. From portable devices like glucose meters and pacemakers to large imaging equipment such as CT and MRI scanners, the internal PCBs must possess extremely high stability and precision. These PCBs need to resist corrosion from harsh chemical environments during disinfection and maintain stable performance over long-term use, ensuring accurate medical diagnosis and patient safety.

4.Aerospace: Challenging Performance Limits in Extreme Environments

This area represents the peak of requirements for PCB technology. PCBs in the aerospace sector must withstand extreme temperature cycles, intense vibration, radiation, and the vacuum of space. They often use special ceramic substrates or high-performance PTFE materials, possessing exceptional thermal stability and dimensional stability. From satellite communication systems to aircraft navigation and control, every PCB undergoes extremely stringent testing and certification. The cost of failure is exceptionally high, making them critical components where the slightest deviation can lead to significant consequences.

Conclusion: From everyday life to the frontiers of technology, the development history of PCB technology is, in essence, an evolution history of the modern electronics industry. With the continued advancement of technologies like Artificial Intelligence and the Internet of Things, PCBs will play an indispensable core role in more innovative fields, continuously connecting and driving our future world.