The selection strategy of PCB Assembly Factory

The selection of a PCB Assembly Factory is a crucial strategic decision in the manufacturing of electronic products. It directly affects the quality, cost, delivery time, and ultimately the market competitiveness of the products. An outstanding partner not only offers excellent manufacturing services, but also becomes a solid support for the success of your products. Therefore, when making a choice, enterprises must conduct a systematic evaluation and consideration from multiple core dimensions.

Core assessment indicators

When choosing a partner, one should first focus on its hard power and quality assurance system. This mainly includes the following aspects:

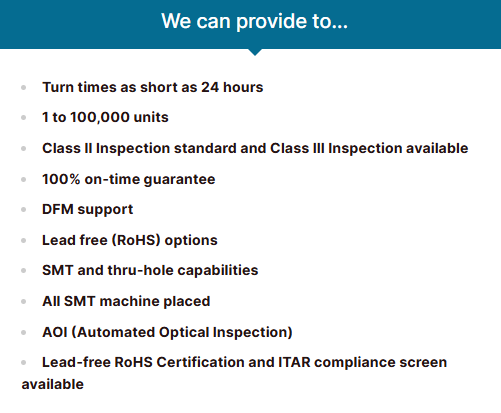

1:Process capability and technical expertise: Thoroughly understand the types of PCBs that the factory can handle (such as rigid boards, flexible boards, rigid-flex boards), the number of layers, the minimum line width and spacing, as well as the assembly experience of precision components like BGA and QFN. At the same time, confirm whether it has comprehensive service capabilities including through-hole mounting, surface mounting, and testing.

2:Quality certification and control system: Preferentially select factories that have obtained international certifications such as ISO9001 quality management system, IATF 16949 (for the automotive industry), or ISO 13485 (for the medical industry). Inquire about their quality control processes, including incoming material inspection, in-process quality control, final product testing, and the application of SPC statistical process control.

3:Equipment and Automation Level: Modern high-speed surface mounters, precision screen printers, reflow ovens, as well as AOI (Automatic Optical Inspection) and X-Ray inspection equipment are the foundation for ensuring production efficiency and product consistency. Advanced factories also introduce automated material management systems to reduce human errors.

Soft power and the potential for long-term cooperation

Apart from the hard indicators, the soft capabilities of the PCB Assembly Factory also determine whether the cooperation can be smooth and long-lasting.

1:Communication Efficiency and Supply Chain Management: Evaluate the response speed, the smoothness of communication, and whether there are customer managers or engineers who can proficiently use the language you require. A robust supply chain management system can ensure the timeliness of component procurement and cost control, especially when facing material shortages in the market, its response capability is of crucial importance.

2:Capacity and delivery reliability: Determine whether the factory’s capacity can meet your peak demand, and review its historical delivery records to ensure it strictly adheres to the agreed delivery deadlines. This directly affects your product launch time and inventory management.

3:Service awareness and collaborative spirit: An outstanding PCB Assembly Factory will demonstrate an attitude of actively addressing problems. It is willing to jointly confront challenges in design, process, or materials with you, provide valuable manufacturing design optimization suggestions, and become your true strategic partner.

In conclusion, choosing the appropriate PCB Assembly Factory is a comprehensive decision-making process that requires balancing technical capabilities, quality, cost, service, and long-term cooperation potential, so as to find the most reliable manufacturing foundation for your products.