4-layer PCB manufacturer has become the mainstream in the market not because single-sided or double-sided PCBs have lost their advantages, but because of the complexity and integration requirements of modern electronic products.

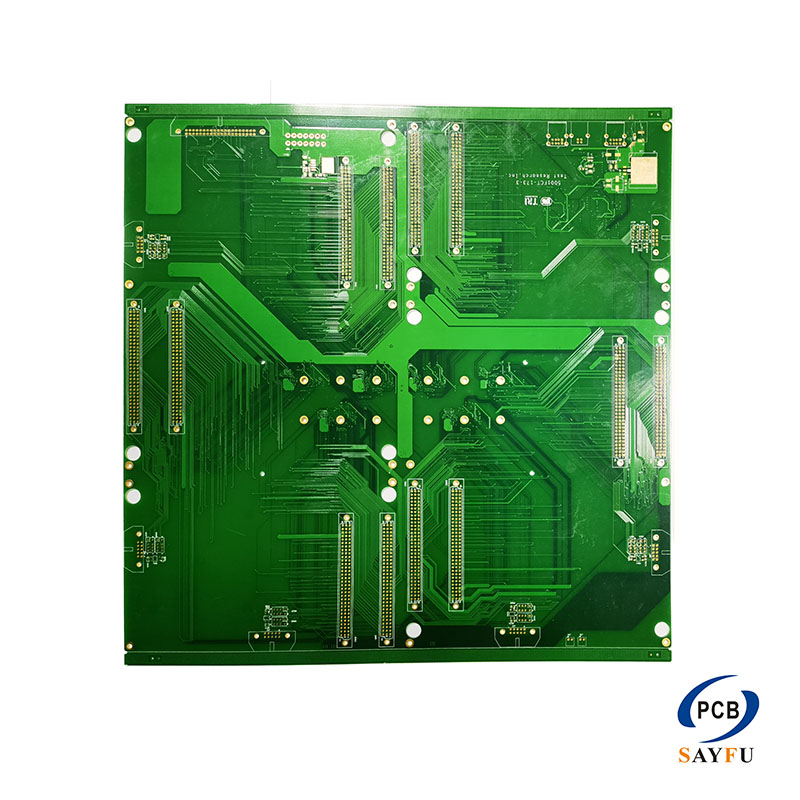

4-layer PCB manufacturer – The preferred choice for realizing product functions

Today, core control chips (such as MCU, MPU, and SoC) for consumer electronics, IoT devices, and industrial controllers typically use fine-pitch BGA or QFN packages, and require connections to DDR memory, flash memory, multiple sensor interfaces, and wireless communication modules (such as Wi-Fi and Bluetooth). These complex circuit connections, stable power supply, and complete ground plane shielding have far exceeded the limits that a single-sided or double-sided PCB can handle through positive and negative side routing. Therefore, 4-layer PCB manufacturer can provide multi-layer board solutions that include dedicated power layers and ground layers, which has become the inevitable choice for realizing product functionality.

The rigid requirements for performance and integration degree

Modern electronic products have increasingly strict requirements for signal integrity, power integrity, and electromagnetic compatibility (EMC). The 4-6 layer PCB, with its built-in complete ground plane and power plane, offers advantages that single or double-sided PCBs cannot match: Firstly, it provides a low-impedance return path for high-speed digital signals, significantly reducing signal distortion and electromagnetic radiation. Secondly, the dedicated power plane ensures stable and clean power supply for the chips, avoiding system failures caused by voltage drops. Thirdly, the multi-layer structure allows for more dense wiring, significantly reducing the size of the board, which is crucial for portable devices that aim for lightness, compactness, and small size.

The market positioning of single-sided and double-sided PCBs

Although 4-6 layer PCBs are the mainstream, single-sided and double-sided PCBs have not lost their advantages yet. They merely remain in their indispensable application fields. Their main advantages lie in extreme cost control and mature processes. For products with fixed functions, simple circuits, and extremely sensitive costs, such as remote controls, children’s toys, simple LED lighting, home appliance control boards, and basic electrical equipment, single or double-sided PCBs remain the most cost-effective choice. In these fields, using multilayer boards is equivalent to having excess performance and is an unnecessary waste. Therefore, there is a stratification phenomenon in the market: high-end complex products drive the prosperity of 4-layer PCB manufacturer, while the vast basic electronics market continues to support the stable demand for single-sided and double-sided PCBs.